50ton Rice Mill Plant Rice Milling Equipment Price

Jiangsu Vichen Composite Material Co., Ltd. / 2022-07-04

- After-sales Service:Spare Parts Available with Competitive Price

- Warranty:One Year

- Type:Rice Mill

- Application:Rice Milling

- Voltage:380V

- Appearance:Vertical

=== Base Info ===

- Model NO.:SD-CF-5800

- Press Materials:Rice

- Press Series:Second

- Condition:New

- Customized:Customized

- Product Name:China Manufacturer Domestic 50tpd Rice Mill Price

- Capacity:50 Tons Per Day

- Operator:4-5 Persons

- Price:Negotiable

- Features:Easy Installation, Easy Operation, Low Price

- Main Markets:Nigeria, Ghana, Uganda, Ivory Coast, Indonesia...

- Operation:Automatic Working

- Raw Material:Paddy

- Uasge:Grain Processing Machine

- Markets:Nigeria, Ghana, Tanzania, India, etc..

- Related Products:Rice Stone Removing, Color Sorter, Packing Machine

- White Rice Rate:72%

- Broken Rate:Less Than 5% Broken Rice Rate

- Finished Rice:High Quality, No Paddy

- Transport Package:Wooden Cases, 20′gp or 40′hq Containers

- Specification:depends on the capacity

- Trademark:SIDA

- Origin:Henan, China

- HS Code:8437800000

- Production Capacity:From 5 Tons Per Day to 300 Tons Per Day

=== Description ===

Basic Info.

Model NO. SD-CF-5800 Press Materials Rice Press Series Second Condition New Customized Customized Product Name China Manufacturer Domestic 50tpd Rice Mill Price Capacity 50 Tons Per Day Operator 4-5 Persons Price Negotiable Features Easy Installation, Easy Operation, Low Price Main Markets Nigeria, Ghana, Uganda, Ivory Coast, Indonesia... Operation Automatic Working Raw Material Paddy Uasge Grain Processing Machine Markets Nigeria, Ghana, Tanzania, India, etc.. Related Products Rice Stone Removing, Color Sorter, Packing Machine White Rice Rate 72% Broken Rate Less Than 5% Broken Rice Rate Finished Rice High Quality, No Paddy Transport Package Wooden Cases, 20′gp or 40′hq Containers Specification depends on the capacity Trademark SIDA Origin Henan, China HS Code 8437800000 Production Capacity From 5 Tons Per Day to 300 Tons Per DayProduct Description

50Ton Rice Mill Plant Rice Milling Equipment Price

Our rice processing machine adopts advanced technology, scientific and mature process. A complete rice milling plant includes cleaning--destoning--husking--separating-- milling--polishing--grading--color sorting--packing, and the final white rice is first grade quality, which can meet international import and export standards.

We have exported and installed many rice processing lines in Nigeria, Togo, India, Uganda, Indonesia, South Africa, Tanzania, etc.And our customers give us very good response.

Flow chart of rice milling machine for sale

Vibrated cleaner → Destoner → Rice husker → Rice Separator → Rice Mill → Rice polisher → Rice Grader → Rice Color Sorter → Packing

Introduction of rice milling machine for sale

1. Vibrated cleaner: Cleaning the paddy

2. Destoner: Separating small stones from the paddy

3. Husker: Removing the husk from the paddy

4. Separator: Separating the husk from the brown rice /unhusked paddy

5. Rice Mill: From paddy to rice

6. Rice polisher: The polishing machine will make the white rice more shining and more smooth, thus to increase the quality of rice

7. Rice grader: separate different quality rice and separate broken rice from the good ones.

8. Rice color sorter: The rice we get from above steps still have some bad rice, broken rice or some other grains or stones, so here we use color sorting machine to select the bad rice and other grains. Color sorting machine is an important machine to ensure we can get high quality rice.

9. Packing machine: this packing machine includes weighing, packing, sealing and conveying machine, can pack 5-50kg per bag.

Features of complete rice processing machine:

1. This rice processing line can be used to process both long-grain rice and short-grain rice(round rice), suitable to produce both white rice and parboiled rice, high output rate, low broken rate;

2. Use vertical type rice whiteners, high yield bring you high profit;

3. Equipped with pre-cleaner, vibration cleaner and de-stoner, more fruitful on impurities and stones removing.

4. Two water polishers and rice graderes will bring you more shining and higher precision rice;

5. The pneumatic rice hullers with auto feeding and adjustment on rubber rollers, higher automation, more easy to operate.

6. Usually use bag type dust colloctor to collect in high efficiency the dust, impurities, husk and bran during processing, bring you good working environmental; The pulse dust collector is optional;

7. Having high automation degree and realizing continuous automatic operation from paddy feeding to finished rice packing.

8. We can customize the proposals and specifications to meet the requirements of different users.

Technical data of rice milling machine for sale

| Capacity | Power |

| 1 ton per hour | 24kw |

| 20 tons per day | 53kw |

| 30-40 tons per day | 77.5kw |

| 50-60 tons per day | 120kw |

| 70-80 tons per day | 190kw |

| 100-120 tons per day | 330kw |

| 150 tons per day | 520kw |

Detailed parts show

Pictures of rice processing machine:

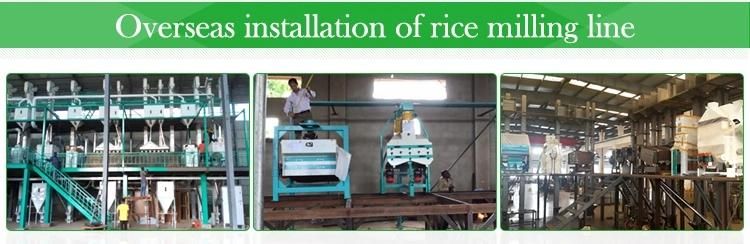

Installation pictures

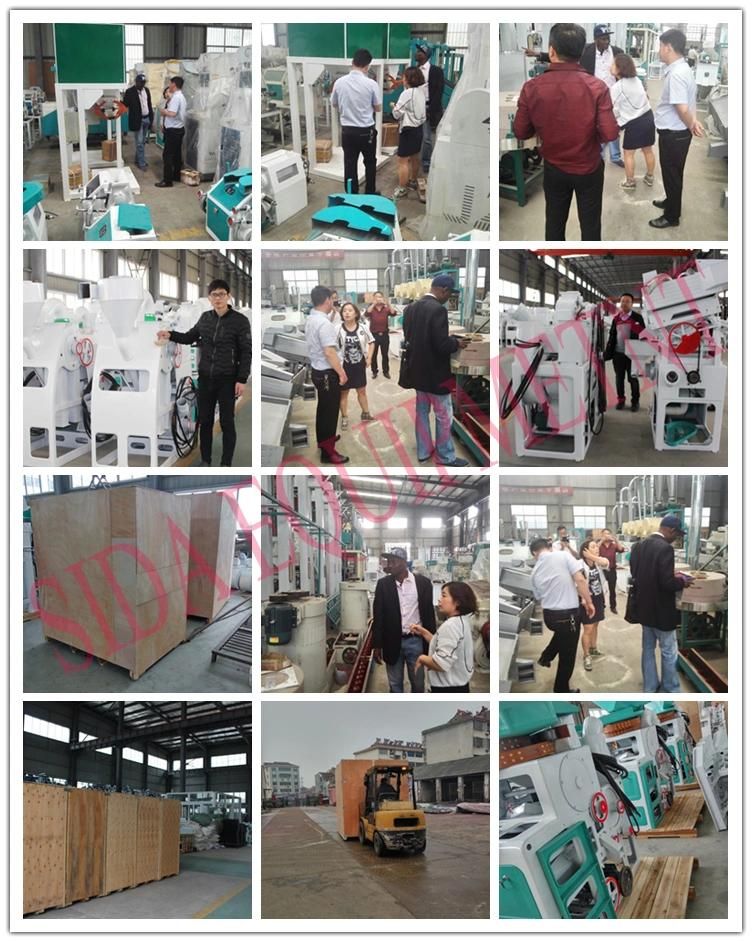

Customer visiting

Packing & Delivery

Company profile

Zheng Zhou Sida Agriculture Equipment Co., Ltd. is a manufacturer of rice processing machines. We can supply 5-300ton/day complete rice mill line(Parboiled rice line) and different kinds of rice processing machines like husker,destoner,rice grader, color sorter, paddy dryer, etc. Our rice equipment have been exported and installed in rice successfully in Nigeria,Thailand, India, Sri Lanka, Indonesia and so on. Our main markets cover Africa (such as Nigeria, Ghana,Cameroon, Gabon and so on), Europe, America.... Welcome to visit our factory!

FAQ:

1. How can we see the machine?

You are warmly welcome to visit our factory, and we have the working machine in factory, our engineers will explain you the machines details one by one.

2. How many labors to operate machine?

The standard line just need about 3-5 labors to operate.

3. Will you help us to build the factory and install the machine?

Yes, it will take about 30 days for 2 people to install the whole production line. And our engineers will be sent to your site to help you for the installation.

4. Will you offer training?

Yes, free training will be offered after the installation.

5. Where is your factory?

Our factory is located in Zhengzhou city which is the capital of Henan province, China. It is very convenient for you to visit here, no mater you come here by train or by air.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23