Automatic Liquid Condiment White Vinegar Edible Oil Tomato Sauce Honey Shampoo Cleaning ...

Shanghai Atxel Industrial Co., Ltd. / 2022-07-04

- Condition:New

- Customized:Customized

- Voltage:Customization

- Composition:Filling Machine

- Processing Material:Filling Machine Part

- Process:Welding Polish etc

=== Base Info ===

- Model NO.:GH-GF

- Usage:Liquid

- Certificate:SGS

- Size of Bottle Can Be Handled:0.25-2.5L

- Automation:Fully Automatic

- Transport Package:Wooden Case

- Specification:12cm

- Trademark:Ganghong

- Origin:China

- HS Code:84223090

- Production Capacity:100,Year

=== Description ===

Type

Production capacity

Filling precision

Gas Consumption

Air source pressure

Machine Power

Power

Size

Weight

YGF12-5

3000

±2%

0.25

0.6-0.8

1.5

2.5

1700X1400X2750

1500

YGF16-5

4000

±2%

0.3

0.6-0.8

2.2

3.4

1800X1650X2750

2500

YGF18-6

5000

±2%

0.4

0.6-0.8

3

4.2

2200X2000X2750

3500

YGF24-6

5000

±2%

0.5

0.6-0.8

4

5.3

2500X2200X2750

4500

YGF32-8

7000

±2%

0.6

0.6-0.8

4

5.3

2900X2400X2750

5500

YGF40-12

8000

±2%

0.7

0.6-0.8

5.5

6.4

3100X3000X2750

7500

YGF50-18

10000

±2%

0.8

0.6-0.8

5.5

6.4

4000X3500X2750

8500

Machine Details

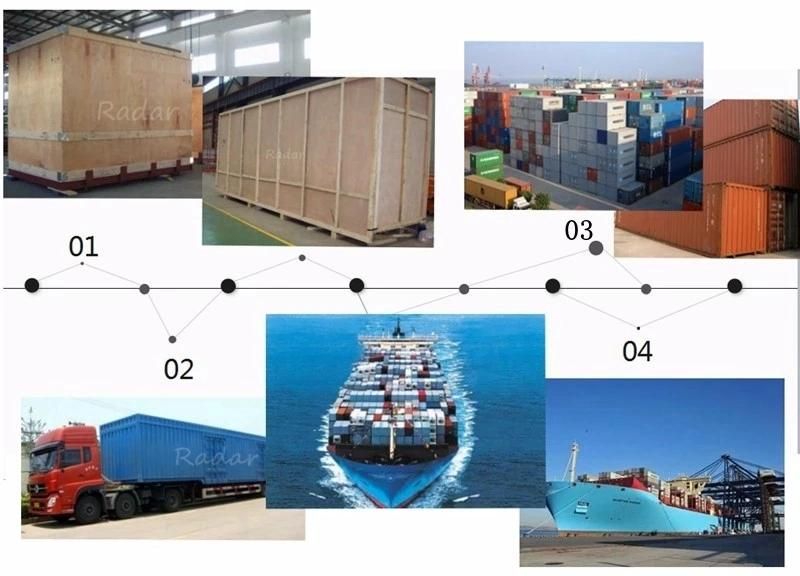

Packing & Delivery

Packaging Details: Standard export packing suitable for long distance land and sea transportation.

Shipping Detail: Shipped in 45 working days after advance payment and sample bottles and capers received.

Loading Port: Shanghai, Ningbo,Shenzhen

Our Advantage:

No matter whether you're a newcomer or a sectoral expert - we have the specialists who can provide the comprehensively can-do support you need for planning a new facility in terms of not only actual beverage production, but also filling, packaging, utilities and logistics. In closely responsive consultation with you, from a multiplicity of possible options, we select the technologically and commercially most effective variant, handle the design and planning work, and bring the project to a successful conclusion at your chosen location. Sunswell is not only the consultant here, but also takes responsibility for executing the entire project.

FAQ

1) When can I get the price?

We usually quote within 24 hours after we get your inquiry.If you are very urgent to get the price, please call us or tell us in your email so that we will regard your inquiry priority.

2) Are you factory or trading company?

We are factory and manufacture.

3) Where is your factory located? How can I visit your factory?

We are located in Wuxi, you can fly to Changzhou airport or Wuxi airport. We can pick you up from the airport or your hotel.

Welcome to visit us!

4) How to place my order?

Just contact us via Trader Manager, E-mail, Skype or telephone to confirm the product, make the deposit then we will start to manufacture.

5) What about the transportation and delivery date?

Normally we use shipment to transport the goods.It is about 25-40 days.It also depends on which country and port you are.

It could be shorter if you need to send the goods like Asian.

If there are some emergencies we can send the goods via air express, as long as you afford the traffic expense.

6) The After-sales Service of Ganghong Machine

1. After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools

2.After the commissioning, we will package the equipment by standard export package for shipment.

3.According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

4.Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the customers' project.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23