Industrial Brewing Project 2000L / 20bbl Beer Making Machine

Jinan Jotop Import and Export Trade Co., Ltd. / 2022-07-05

- Processing Material:Water,Malt,Hops,Yeast

- Application:Beer

- Customized:Customized

- Certification:CE, ISO9001, TUV

- Power Source:Electric Steam,Gas,Direct Fire

- Automatic Grade:Semi-Automatic

=== Base Info ===

- Model NO.:MT-1000L

- Material:SUS304 Stainless Steel

- Cooling Unit:Chiller with Glycol Tank

- Control Unit:Temp. Controller, HMI, PLC or Touching Screen

- Thickness:Inner Wallet 3mm, Outer Wallet 2mm

- Voltage:220V,380V

- Dimension(L*W*H):Depending on Capacity

- Weight:Depending on Capacity

- Welding:Arc Argon Protection

- Warranty:3 Years for Tank

- Insulation:Polyurethane Foam

- Polish Finish:0.4-0.6UM

- Brewhouse Heating:Steam Jacket , Electric Tube, Direct Fire

- Technology:Offer Auto CAD and 3D Design Drawing

- After-Sales Service:Installation and Equipment Commission

- Capacity:2000L Beer Making Machine

- Transport Package:Plastic Film, Plywood Case; Container;

- Specification:Customized

- Trademark:METO

- Origin:Jinan, China

- HS Code:84384000

- Production Capacity:10 Set,Sets Per Month Stainless Steel Brewhouse

=== Description ===

Mashing Process:Decoction.Infusion.Multi-step infusion

Heating source:Steam,Electric,Gas

SUS304/Red copper

Interior:2.5-3mm

Exteior:3-4mm

Whirlpool Tank

Drying hop port to brew IPA

Dimple Plate Cooling jacket

Carbonation port to fill CO2

HMI

1.LCL/FCL(20GP/40GP/40HQ).

2.Packed with plastic film in fumigation free wooden case or fixed with iron frame.

3.Up to export standard, suitable for delivery.

4.Customer's requirements available.

1. Free consultation service before, during, and after sales Layout plan in 3D or CAD drawings of your brewery;

1. Free consultation service before, during, and after sales Layout plan in 3D or CAD drawings of your brewery;2. Professional engineers going abroad for the installation ,debugging, and training, all the travelling cost and

locate food, and hotel shall be afforded by the buyer

3. The installation period is about 15 days including assembling brewing tanks and training the operator. It is

free of charge within 15 days. The buyer will be charged USD 50 per day for each engineer for the extended

installation.

4. Round the clock assistance via phone, e-mail, Skype, Whatsapp, MSN, or any other communication method

available to the customer.

5. Assisting purchased Facilities by seller including bottling system, steam boiler, water treatment, etc. should

be installed separately. If needed, cost calculate additionally.

6. Brewing technology, brewing formula, can be offered available

7. More spare parts are available to offered freely.

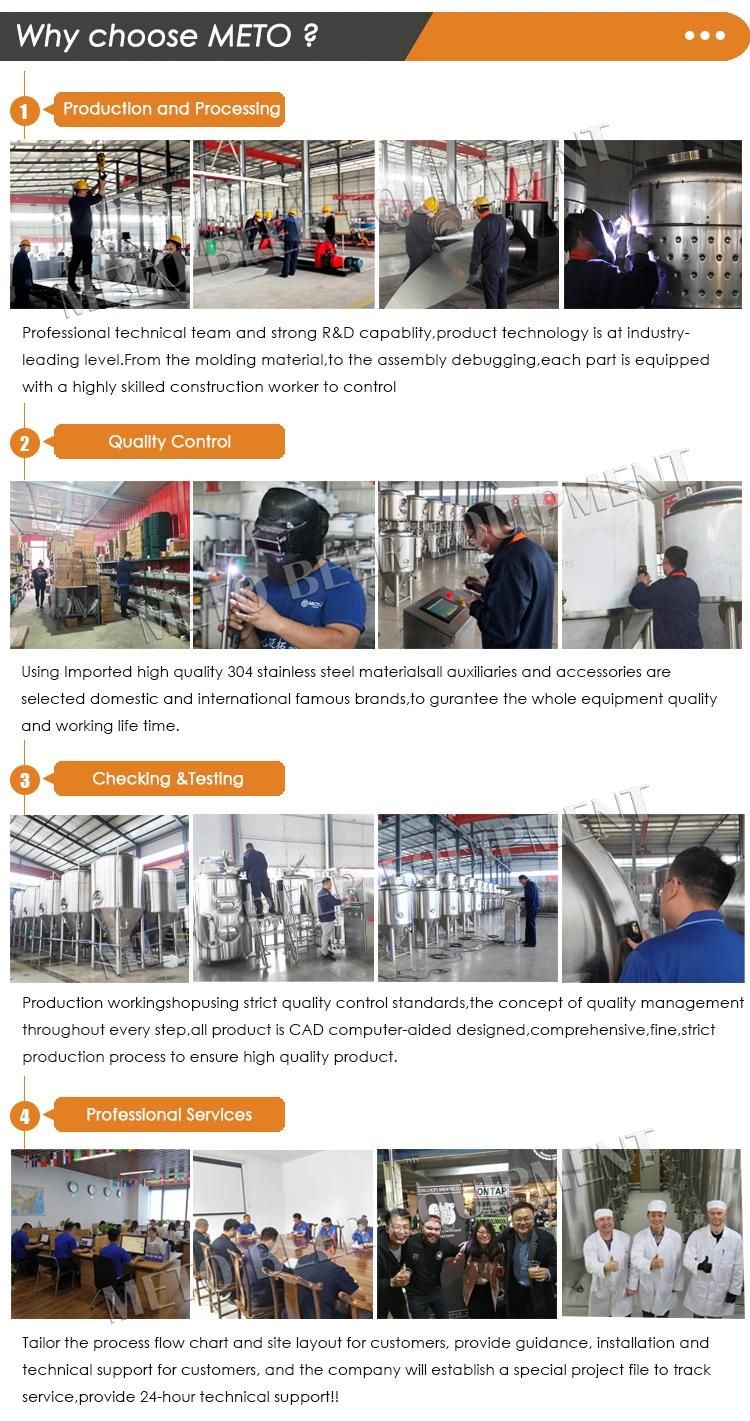

METO is a professional manufacturer of beer brewing equipment. We mainly have the following kinds of

equipment: including 100L, 200L, 300L, 500L, 1000L, 2000L etc. We can produce the equipment according

to our clients' requirements.

1.Q: Are you a manufacturer?

A: Yes, we have been in providing the professional products in this field for 10 years.

2.Q:What exactly does the 36 month warranty cover?

A:36 month warranty cover all the main tank.one years for the accessories and spare parts.

3.Q: Can your factory produce equipment according to our drawing or samples?

A: Yes, we can do.

4.Q:Is the 15 day set-up by your engineers mandatory, or can we opt to pass on that service?

A:Yes ,you can,we will offer the manual or video to let you know how to connect the equipment.

5.Q: How to calculate the daily output? How many fermenters do I need?

A: Usually theequipment models such as 300L and 500L are only 300L, 500L wort for mashing capacity.

Beer production is according to your fermentation process requirements and the number of fermenters configured.

6.Q: How you pack the products?

A: Normally as the export standard packaging or as you required.

7.Q: What is your available port of shipment?

A: Qingdao port,shanghai etc.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23