Hot Sale High Quality Complete Automatic Aseptic Milk Powder Production Processing Line ...

Shanghai Yongguan Adhesive Products Corp., Ltd. / 2022-07-05

- Process:Concentration and Dry

- Power Source:Electric

- Certification:CE, ISO

- Automatic Grade:Automatic

- Application:Milk Powder

- Customized:Customized

=== Base Info ===

- Model NO.:JM-MP

- Company:Shanghai Jimei Food Machinery Co.,Ltd

- Product Name:Hot Sale High Quality Complete Automatic Aseptic M

- Final Product:Dry Milk Powder

- Processing:Turnkey Project

- Warranty:1 Year for Free and Lifelong Free Technical Suppor

- Capacity:100kg-1000kg,Hour

- Run:Convenient and Stable

- Condition:New

- Control:PLC,Touch Screen,Simple Operation

- Material:Stainless Steel

- Transport Package:Wooden Cases

- Specification:customized

- Trademark:Shanghai Jimei

- Origin:Shanghai

- Production Capacity:8 Units Per Month

=== Description ===

Basic Info.

Model NO. JM-MP Company Shanghai Jimei Food Machinery Co.,Ltd Product Name Hot Sale High Quality Complete Automatic Aseptic M Final Product Dry Milk Powder Processing Turnkey Project Warranty 1 Year for Free and Lifelong Free Technical Suppor Capacity 100kg-1000kg/Hour Run Convenient and Stable Condition New Control PLC,Touch Screen,Simple Operation Material Stainless Steel Transport Package Wooden Cases Specification customized Trademark Shanghai Jimei Origin Shanghai Production Capacity 8 Units Per MonthProduct Description

Hot Sale High Quality Complete Automatic Aseptic Milk Powder Production Processing Line Equipments Turnkey Project PriceDetailed Information

Raw material | Liquid cow milk, goat milk, camel milk, milk powder dissolving |

Product | The product includes full milk powder, skim milk powder, whey powder, as well as butter solidifying process. |

Capacity | 100KG-1000KG/Hour |

Product package | Tin Can, plstic pouch, paper pouch, can etc. |

Service include | Turnkey project service: design, manufacture, installation, commissioning, training, after-sale service and so on. |

1. Automatic PLC controlled water treatment system

101 Sand filter

102 Activated carbon filter

103 Water softener

104 Precision filter

105 Reverser osmosis

2.Pure water supplying station

201 Electrical control system

202 Storage tank

203 Centrifugal pump

204 Constant pressure system

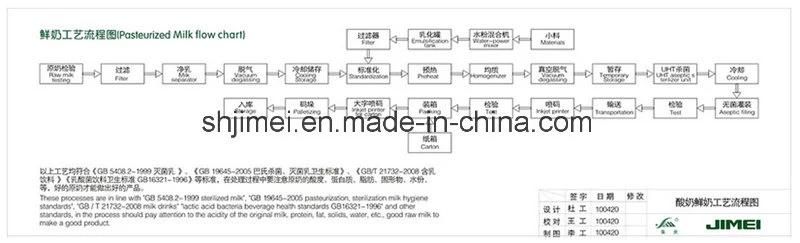

3.Pre-treatment system

301 Stainless steel milk bucket

302 Milk receiving tank

303 Milk weight tank

304 Electronic scales

305 Pipeline flowmeter

306 Duplex Filer

307 Milk separator

308 Buffer tank

309 Plate sterilization machine

310 Vertical cooling milk storage tank

311 Outdoor milk warehouse

312 Beverage pump

313 CIP return pump

4. Batching system

401 Hot water tank

402 Plate heat exchanger

403 Square high speed emulsification tank

404 Water-powder Mixer

405 Mixing tank

406 Oil can

407 Duplex Filer

408 25Mpa Homogenizer

5.Concentration System

501 Three-efficiency concentrating tower

502 Balance tank

503 Beverage pump

504 Cooling water pump

505 Vacuum pump

506 Cooling tower

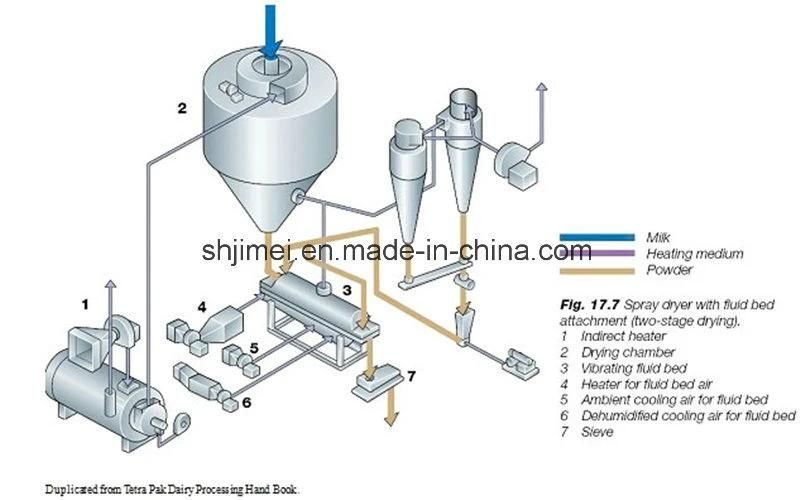

6. Drying system

601 Concentrated milk tank

602 Rotor pump

603 High-pressure pump

604 Electric sieve

605 Spray-drying tower

606 Fluidized bed

607 Milk powder groove

7.Packaging system

701 Tank platform

702 Cans unscrambler

703 Turn cans, sterilization machine

704 UV sterilization machine

705 Automatic can filling machine

706 Screw feeder

707 Vacuum sealing machine

708 Ink jet printer

709 Turn tank machine

710 Buckle cover machine

711 Carton sealing machine

712 Conveyor

713 Packing platform

714 Plastic bag packaging machine

715 Semi-automatic big bag filling machine

716 Sealer

717 Seam bag machine

8.Automatic PLC controlled CIP cleaning system

801 Acid tank

802 Alkali tank

803 Hot water tank

804 Strong acid tank

805 Strong alkali tank

806 Diaphragm pump

807 Pleat heat exchanger

808 Cleaning pump

809 Pipes and valves

810 Steam reduce system

811 PLC controlling System

9.Boiler system

901 Horizontal oil-fired boiler

902 Steam tank

10.Refrigeration system

1001 Refrigeration units

1002 Ice water tank

1003 Ice water pump

11.Refrigeration system

1101 Air compressor

1102 Air filter

1103 Air cooling and drying machine

1104 Gas tank

The milk fat content is standardised in a direct standardisation system. Standardised milk used for producing whole milk powder is not normally homogenized.

In the production of dried whole milk the heat treatment must be so intense that the lipases will also be inactivated. This normally involves high-temperature pasteursation to a negative peroxidase test.

Falling-film evaporators are generally used for concentration, which is carried out in two or more stages to a DS content of 45 - 55%.

Company Information

Zhejiang Xuxiang Mechanical Technolgy Co., Ltd. is branch company of Jimei Holdings Group of China - Shanghai Jimei Food Machinery Co., Ltd. is a collection of scientific research, production and service as one of professional manufacturer of liquid beverage food machinery, high-tech enterprises Within the company has a high-quality science and technology team has a pioneering spirit, a number of independent research and development of new products and a number of national invention patents.

FAQ

1.How long can I receive your reply after I send my inquiry?

We will reply you within 12 hours on workday.

2.Are you a manufacturer or a commercial company?We are a manufacturer, and we have a foreign trade department, we market our own products.

3.What products can you provide?We mainly produce beverage production machinery and equipment.

4.What are the application fields of your products?Our products are mainly used by beverage factories or individuals who want to run a milk production plant.

5.Can you provide custom products?Yes, custom products are our main products. We can develop and manufacture products according to customer's drawing or sample. Saving customer's time on finding corollary equipment.

6.How's your production capacity?Our annual output is about 800,000 sets.

7.How many employees do you have?We have over 100 employees, including several technicians and engineers.

8.How do you ensure your product quality?We conduct inspections in every production procedure, and for finished products, we will take 100% inspection depend on international standards according to customer's requirements.

9.Payment?We will confirm the payment with you when quoting, like FOB, CIF, CNF or others.

In batch production, we accept 30% deposit, balance against the copy of B/L.

T/T is the main payment, and L/C is acceptable as well.

We commonly use sea transportation, using container to deliver the goods through Shanghai Port.

11.Where do you mainly export your products?Our products are mainly exported to Mexico, Saudi Arabia, India, Algeria, Dubai, Congo, African countries, etc.

Our Service

1.Allotted for equipment inspection certificate and manual, to ensure that users properly install and use.

2.Equipment to reach the destination,the company will send engineers to guide installation and commissioning and customer training until satisfied.

3.The warranty period will be free to customers wearing accessories, shelf life outside of my company to provide parts at cost.

4.I provide lifelong maintenance service, including if necessary, to send engineers to the customer at the service.

Trade Information

1. Package- all equipments packed in nylon cloth and plastic film worthy of sea shipping.

2. Delivery- in 30 days upon receipt of down payments.

3. Warranty-all machines & equipments are of one year warranty and life long maintenance offered by seller.

4. Installation- the seller arrange engineer to set up the equipments and train the operation workers for free, till qualified products are produced and maintenance in normal running, the buyer bear the round air tickets and local accommodation for the seller's engineer.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23