300-500kg Breakfast Delicious Sweet Peanut Nougat Candy Bar Processing Line

Shandong Longxing Plastic Film Technology Co., Ltd. / 2022-07-05

- After-sales Service:12 Months

- Warranty:12 Months

- Certification:CE

- Power Source:Electric

- Process:Thermal Processing

- Automatic Grade:Automatic

=== Base Info ===

- Model NO.:LY65LY70LY75LY85LY95

- Customized:Customized

- Material:Stainless Steel,Carbon Steel

- Main Machine:Twin Screw Extruder

- Function:Fully Automatic

- Capacity:100-150g,H 200-250kg,H 300-500kg,H 300-500kg,H 800

- Installation:Engineer Guide

- Transport Package:Film&Wooden Box Packing

- Specification:2.5*1.2*1.5m

- Origin:Jinan, China

- HS Code:8438800000

- Production Capacity:5000 Sets,Year

=== Description ===

Basic Info.

Model NO. LY65LY70LY75LY85LY95 Customized Customized Material Stainless Steel/Carbon Steel Main Machine Twin Screw Extruder Function Fully Automatic Capacity 100-150g/H 200-250kg/H 300-500kg/H 300-500kg/H 800 Installation Engineer Guide Transport Package Film&Wooden Box Packing Specification 2.5*1.2*1.5m Origin Jinan, China HS Code 8438800000 Production Capacity 5000 Sets/YearProduct Description

300-500kg Breakfast Delicious Sweet Peanut Nougat Candy Bar Processing Line

Cereal bars are made of oats, rice, nuts, dried fruits and other main ingredients. It is popular in the market because of

delicious taste, crisp texture, rich nutrition and convenient portability. It has also become the main meal replacement food for fitness people. How to make cereal bars easily?

The cereal bar production line adopts PLC operating system and advanced mechanical structure to realize full automatic

production-continuous feeding, automatic flattening, automatic cutting and cross cutting. Compared with traditional hand-made methods, it reduces a lot of production costs ,improves production efficiency.

By changing the raw material formula, the Cereal Bar making machine can manufacture many differernt type products ,such as cereal

bars, granola bars, peanut candy bars, puffed rice bars, nougat bars, etc. The bar shape can be circular, square, semicircular and triangular.

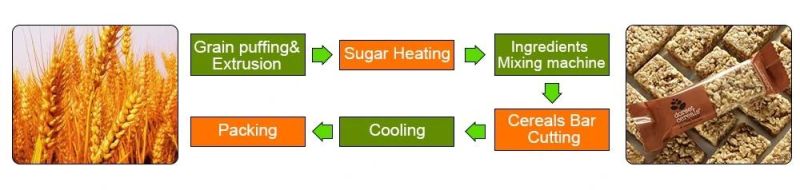

Production process

Production processGrain puffing&Extrusion→Sugar Heating →Ingredients Mixing machine→Cereals Bar Cutting →Cooling→Packing

Cereal bar manufacturing process

Cereal bar manufacturing processRaw Material--Black Rice, Sugar,Nuts,Corn, Barley ,Wheat, Dry Fruit ,Raspberry, blueberry, passionflower ,Sugar

Finished Products--Cereal Bar, Granola Bar, Peanut Candy Bar, Puffed Rice Bar

Machine parameters and characteristics

| Machine Name | Capacity | Dimension |

| 1.Grain puffing machine | 100kg/h | 1320*970*960mm |

| 2.Sugar Cooker | 100L | 1320*970*960mm |

| Sugar Cooker | 200L | 1550*1200*1100mm |

| 3.Mixing Machine | 3-8kg/time | 800*1400*820mm |

| Mixing Machine | 12-20kg/time | 800*1650*1600mm |

| 4.Cereal bar cutting machine /cereal bar press machine | 150-200kg/h | 1880*1110*1160mm |

| 5.Cereal bar packaging machine | 30-200pcs /minute | 3200*600*1000mm |

2Double frequency conversion system control, bag length is set and cut immediately, saving time and film.

3.High-sensitivity electric eye automatic tracking, no need to manually adjust after setting, sealing and cutting size, accurate position, strong and beautiful sealing.

4.Temperature independent PID intelligent control, stable temperature control, better suitable for various packaging materials.

5.Color touch screen display, positioning shutdown, automatic fault diagnosis, the display is clear at a glance.

6.Intelligent human nature parameter design, ordinary personnel can use it skillfully in a short time. Reduce the professional skills requirements of operators.

7.A variety of cutting packaging shapes: straight, popcorn, corrugated, continuous bag, etc.

8.Suitable for moon cakes, bread, biscuits, candies, medicines, daily necessities, hardware parts, paper boxes, plastic products or all kinds of solid objects with regular shapes.

Finished product site machine diagram

Cereal bars are cereals such as oats, rice, corn and other cereals as the main raw material, using high viscosity syrup bonded into a block, stick-shaped products; in addition to the main raw material cereals, the product will also add nuts, dried fruit, candy, chocolate and other spreads; the current domestic market sales of cereal bar products are mostly foreign imports, the product is generally in the form of a single layer, that is, the surface decoration, bottom support or the entire package added Flavoured coatings, such as chocolate coating, butter, condensed milk coating, etc.

Cereal bars are cereals such as oats, rice, corn and other cereals as the main raw material, using high viscosity syrup bonded into a block, stick-shaped products; in addition to the main raw material cereals, the product will also add nuts, dried fruit, candy, chocolate and other spreads; the current domestic market sales of cereal bar products are mostly foreign imports, the product is generally in the form of a single layer, that is, the surface decoration, bottom support or the entire package added Flavoured coatings, such as chocolate coating, butter, condensed milk coating, etc. All machines are made of food-grade stainless steel and the conveying lift is also made of food-grade PVC. The entire production line is made of safe and harmless materials selected by our technical procurement staff after careful selection. The internal accessories are all made of well-known domestic brands and are of high quality.About our companySHANDONG LOYAL INTELLIGENT MACHINERY CO., LTD. is a manufacturer of snacks extruder machine, hot air drying Machine , frying system, industrial microwave system , biscuit making machine, cereals bar making machine, fruit and nuts process making machine, instant noodle process machine and a standing director of China Food and Drying Equipment Industry Association.

All machines are made of food-grade stainless steel and the conveying lift is also made of food-grade PVC. The entire production line is made of safe and harmless materials selected by our technical procurement staff after careful selection. The internal accessories are all made of well-known domestic brands and are of high quality.About our companySHANDONG LOYAL INTELLIGENT MACHINERY CO., LTD. is a manufacturer of snacks extruder machine, hot air drying Machine , frying system, industrial microwave system , biscuit making machine, cereals bar making machine, fruit and nuts process making machine, instant noodle process machine and a standing director of China Food and Drying Equipment Industry Association.The self-developed twin-screw extruder and single-screw equipment of SHANDONG LOYAL INTELLIGENT MACHINERY Machinery have been used in production: puffed snack food, breakfast cereal corn flakes, fried pasta, bread crumbs, fruit chips, baby food, textured soy protein (TSP) food, fish feed and pet food. A variety of snack production line supporting products.At the same time, the batching, drying, flaking, baking, frying and spraying equipment matching the twin-screw extrusion system have all achieved independent design and production.

Our company can provide food production equipment, process, formula development and application for a wide range of users. We are able to provide customers with complete project solutions, advice, planning, project design and engineering for food plants according to their specific requirements. Complete turnkey systems, centralized control systems, complete plant automation projects. Provide the installation, commissioning of machines and training of workers for customers.

Shipping Pictures

Customer Visits

Customer Visits Honor certificate

Honor certificate

FAQ

1. who are we?

We are based in Shandong, China, start from 2019,sell to South America(15.00%),South Asia(12.00%),Southeast Asia(11.00%),North America(10.00%),Africa(10.00%),Northern Europe(8.00%),Western Europe(7.00%),Eastern Europe(6.00%),Central America(5.00%),Southern Europe(5.00%),Mid East(4.00%),Oceania(3.00%),Eastern Asia(2.00%),Domestic Market(2.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Industrial Microwave Oven,Biscuit Making Machine,Food Extruder Machine,Instant Noodle Machine,Automatic Packaging Machine

4. why should you buy from us not from other suppliers?

1. Provide customers with a complete set of designed mechanical solutions and project cost accounting.

2. Provide customers with the best price and high quality machine

3. Provide installation, debug machines for customers, and train workers.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,DDP;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,Credit Card,PayPal,Western Union,Cash;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23