Automatic Extruded Dog Food Feed Pellet Making Machine

Qingdao Baigu Plastic Products Co., Ltd. / 2022-07-05

- Warranty:12 Months

- Power Source:Electric

=== Base Info ===

- Model NO.:TSE70

- Process:Extruding

- Automatic Grade:Automatic

- Application:Dog, Fish, Cat, Bird

- Feed Type:Grain

- Customized:Customized

- Output:100-2500kg,H

- Certification:CE ISO9001

- Voltage:220V,380V,415V

- Material:Stainless Steel

- Model:Tse65,70,75,85,90,95,120

- Screw Material:38CrMoAl

- Energy:Elctrical,Diesel Oil,Fuel Gas

- Motor:Chinese Brand, ABB, Siemens, etc

- After Sales Service:Engineers Available to Service Overseas

- Transport Package:Wooden Case Packing

- Specification:20*2.0*3.0m

- Trademark:Jinan Sunward

- Origin:China

- HS Code:84388000

- Production Capacity:20 Lines Per Months

- Package size per unit product:6000.00cm * 220.00cm * 420.00cm

- Gross weight per unit product:10000.000kg

=== Description ===

Basic Info.

Model NO. TSE70 Process Extruding Automatic Grade Automatic Application Dog, Fish, Cat, Bird Feed Type Grain Customized Customized Output 100-2500kg/H Certification CE ISO9001 Voltage 220V/380V/415V Material Stainless Steel Model Tse65/70/75/85/90/95/120 Screw Material 38CrMoAl Energy Elctrical/Diesel Oil/Fuel Gas Motor Chinese Brand, ABB, Siemens, etc After Sales Service Engineers Available to Service Overseas Transport Package Wooden Case Packing Specification 20*2.0*3.0m Trademark Jinan Sunward Origin China HS Code 84388000 Production Capacity 20 Lines Per MonthsPackaging & Delivery

Package size per unit product 6000.00cm * 220.00cm * 420.00cm Gross weight per unit product 10000.000kgProduct Description

Automatic Extruded Dog Food Feed Pellet Making Machine

The dog food pellet-making machine can produce dry food for all breeds and all ages. It mainly takes cereals powder, bone meal(fresh bone), meat powder(fresh meat), milk powder, wheat flour, salt, vitamins, chicken oil, beef tallow, and so on for production.

Main advantages of dog food pellet making machine:

1. Improve the palatability of pet food;

2. Change or improve the nutritional value of pet food;

3. Improve pet food digestion and absorption rate;

4. Change the shape and structure of pet food, making it easy for pets to eat;

5. Change the content of different nutritional indicators of pet food, and can reduce the moisture of pet food to extend pet food lifetime;

6. Change the bulk density of food, extrusion granulation, briquette increase the bulk density of food;

7. kill all kinds of mold, salmonella, and other harmful substances to improve the safety of pet food;

Our dog food pellet-making machine also can produce dry cat food, bird feed, monkey food, floating and sinking fish feed for many fish species, shrimp and crabs feed, etc.

1. Dry pet food samples for reference:

2. Various models of dog food pellet making machine:

Model (TSE65/70): 150-250kg/hr

mixer → screw conveyer → TSE65 twin-screw extruder → hoister(air conveyer) → 5-layer 5 meter drying oven → single drum flavoring line → cooling machine → packing machine(optional)

Model (TSE75): 350kg/hr

Model (TSE85/90/95): 350kg/hr

Model (TSE120):2000-3000kg/hr

mixer → screw conveyer → extruder → hoister(air conveyer) → 5-layer 8 meter drying oven → double-drum flavoring line → cooling machine → packing machine(optional)

Model (TSE85): 500kg/hr

Model (TSE90):1000kg/hr

Model (TSE95):1500kg/hr

Model (TSE120):2000-3000kg/hr

raw materials mixing system → screw conveyer(bucket elevator) → Storage hopper → steam pre-conditioner → TSE85/TSE90/TSE95 twin-screw extruder → hoister(air conveyer) → 7-layer 8 meter drying oven (bigger ovens) → double-drum flavoring line → cooling machine → Storage bin → packing machine(optional)

3. Technical parameters:

| Model | TSE65 | TSE70 | TSE85 | TSE90 | TSE95 | TSE120 |

Output | 150kg/h | 250kg/h | 500kg/h | 1000kg/h | 1500kg/h | 2500kg/h |

Installed power | 80kw | 100kw | 150kw | 180kw | 200kw | 300kw |

Dimension(m) (L×W×H) | 15×2×3 | 22×2×3 | 28×3×3.5 | 40×5×6 | 50×5×6 | 55×5×6 |

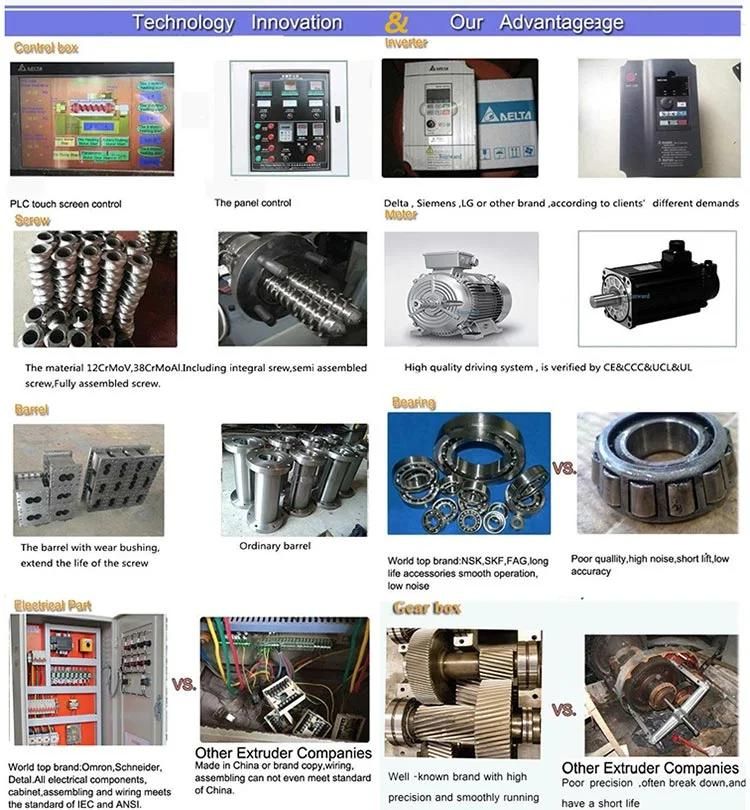

4. Our advantage:

5. Our service:

(1) Free consultation service for all processes;

(2) Free project planning and design services;

(3) Free debugging till every machine running well;

(4) Free delivery management for loading, shipment, and transportation;

(5) Free workers training of equipment maintenance and operating;

(6) Free new production techniques and formulas after sales;

(7) 1-year complete warranty and lifetime maintenance service and cost price spare parts.

6. After service photos

7. Company information

Jinan Shengrun Machinery Co., Ltd, established in 2009, is a professional manufacturer engaged in the research, development, production, sale, and service of puff snacks machine, corn flakes machine, Cheetos machine, fish feed machine, dog food machine and so on. We are located in Jinan with convenient transportation access. Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction. In recent years, our company has introduced a series of advanced equipment including extruder, dryer, flavoring machine, cutter, mixer, etc. In addition, we have obtained C E, S G S, I S O 9 0 0 1 certificates. With efforts of all, our good quality and after-sale service have gained well-known customers' approval at home and abroad. Our products are not only sold well in the domestic market but also exported to more than 100 countries such as United States, England, Hungary, Germany, France, Poland, Korea, Spain, Saudi Arabia, Uzbekistan, Nigeria, Nepal, Indonesia, India and so on. Until now, there are not only direct customers, but also some long-term cooperation agents all over the world. OEM and ODM orders are also welcomed. Whether selecting a current product from our catalog or seeking engineering assistance for your application, sincerely welcome to consult with our customer service center about your sourcing requirements. Providing high-quality products is our goal, and winning with our customers is our philosophy.

8. Packaging and Delivery:

9. FAQ

A. We will pack all necessary machines into wooden cases. For the drying machine, and heavy extruders, we will fix them in the container with very strong iron wire.

B. If by LCL for small quantity machines, we will let send to QINGDAO port for loading.

C. If need containers, our trucks will take the containers from port to our factory for professional and safely loading, and then return to port for shipment.

I. What's the pre-sale service of your company?

Related machines' technical parameters will be supplied to the customer.

1. According to the customer's factory size, the factory layout can be provided in advance.

2. According to the customer's material cost, general formulation can be prepared well.

3. Special machine can be supplied at the customer's request.

4. Professional Advice about the Market, machines, processing, materials, packing can be supplied.

5. Suggesting professional ship agent or helping book ship as customer request.

II. What's the after-sale service of your company?

1. Allocation chart as the buyer's request will be supplied.

2. Operation manual will be supplied after shipment.

3. One-year warrantee, life time maintenance with cost price.

4. Free easy broken spare parts will be sent with container.

5. The First installation can be done by an engineer.

6. Training workers in customer's factory.

III. If machines wearing parts need changing, what should we do?

We can offer the wearing parts all the time, and offer video.

IV. What are the payment terms if we want to buy the machines?

L/C, T/T 30% down payment, 70% balance before delivery.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23