Automatic HDPE Plastic Bottle Blow Molding Extrusion Blowing Moulding Making Machine

Zhangjiagang Goliker Metal Products Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. STCY70 Multi Layers Request Automatic Blow Machine Auto-Deflashing Device Yes Second Name Blow Moulding Machine Third Name Extrusion Blow Molding Machine Motor Siemens After Sales Service Engineer Overseas Working Raw Material HDPE Making Method of Parison Extrusion-Blow Molding Automation Automatic Computerized Computerized Certification CE, ISO9001:2008 Transport Package Iron Tray or Wooden Case Specification CE, ISO9001 Trademark SINO-TECH Origin Made in China HS Code 84774010 Production Capacity Depending on Your SampleProduct Description

Automatic Plastic bottle Blow Molding Machine extrusion blow moulding machine1. Suitable products

1~30L PE, HDPE, PP bottles,jerry can,barrels...

Applications: milk/ yogurt bottles, food pack containers, plastic jars, chemical bottles, cosmetic bottles, lubricant oil bottles, household bottles, detergent bottles, shampoo bottles, oil bottles...

2. Station

The machine is double station double head, cycle time 19s,

per hour can make 360pcs bottles, and per day can make about 8640pcs bottles(basis on 4L bottle),

If customers do not need so much production, we also have smaller single station single head machine, per day it can make about 4320pcs.

( our engineers will make complete solutions according to customers bottle and capacity demands.)

This machine also can produce 15L 20L barrel,each hour capacity is 90-95pcs.Each day capacity is about 2280pcs.

3. Die head

This machine is using single die head to make 10-20L barrels.

However, the die head can also be changed to double die head, triple die head and 4 head to be able to make other smaller size bottles.

Single die head (10~20L)

Double die head (3~5L)

Triple die head (0~750ml)

Four die head (0~300ml)

Changing the die head system takes around 1.5~3h, this also included heating time.

4.Mould - Aluminium 7075# inserted beryllium copper or 4Cr13 stainless material

the best blow molding mould material, aluminium mould has good cooling, and beryllium copper is very durable as well.

4Cr13 mould materal is good strength with longlife time use.

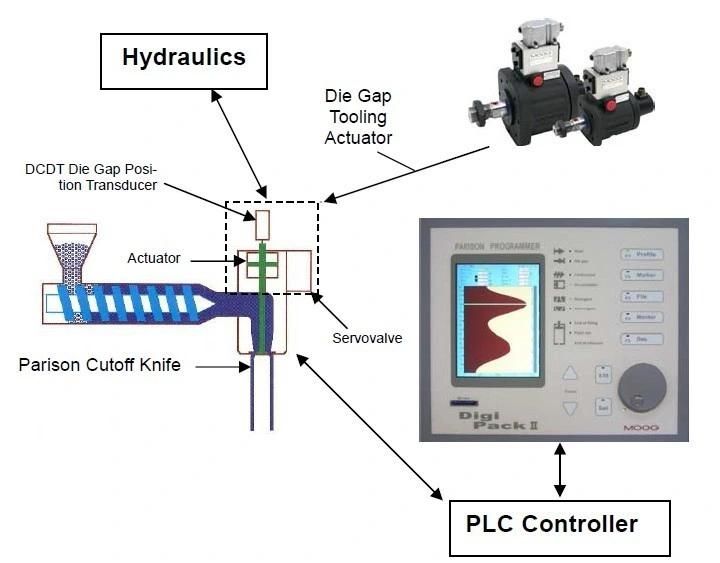

5.Parison control system is a program to change the parison thickness,As the plastic is extruded from the die head,the programming can:

1. Reduce the plastic use

2. Improved wall thickness distribution

3. Reduce cooling time

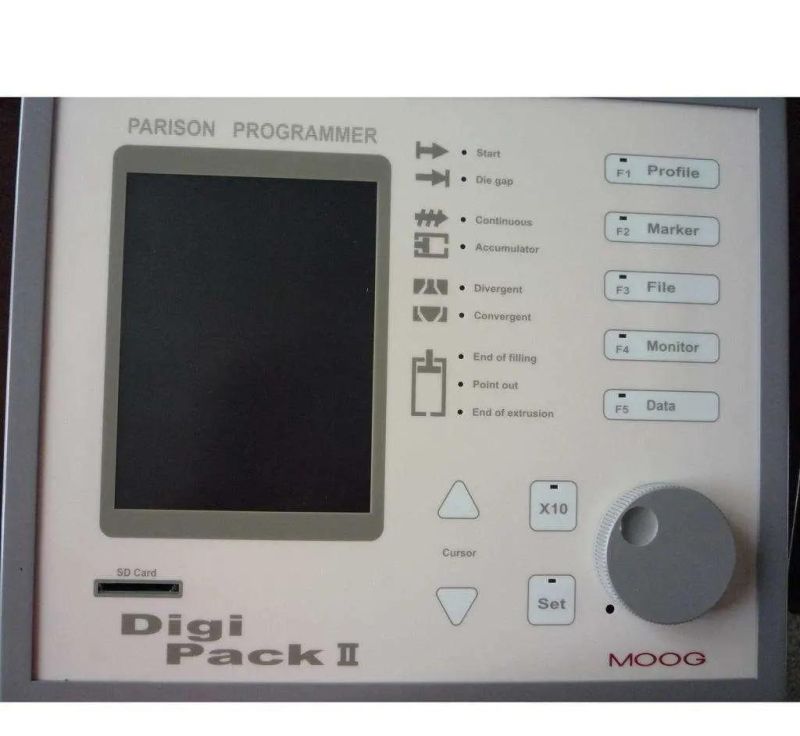

Do we have to use MOOG parison system?

No, We also have many customers they do not use MOOG parison control system, as on our machine's die head, we also can manually adjust the die gaps, from which it can also control the thickness and weight of bottles.

MOOG is more precision, and more easy to do the adjust. It also depends on your ending customer demands and markets.

But for some special designed blow molding items & accumulation type blow molding machines,MOOG is indispensable, it has to use MOOG.

Asone of the biggest factory for blow molding machine in China, we have already exported to over 60 countries in the world, like America, England, Sri Lanka, Italy Switzerland, Newzealand, Egypt.etc.

Maximum Volume: 30 litter

Material: HDPE, PP, PVC, PETG etc.

View Stripe matchable

Easy operation

Automatically

1>Double station and single satation

2>Single mould head to six mould head

3>Single Layer or Double layer with View Strip line

4> It can match auto-deflashing device, Leak detector, Chiller and crusher recycle system.

5> The daliy output(24 hours) can reach approximately from 6000 to 8000pcs; It can produce from 0.2-5L plastic hollow bottle products.

A.Brief Introduction

DMK-L series are fully-automatic pet stretch-blow molding machines(preheat). It has 3 to 16 cavities and the maximum capacity of the products is 2000mL. It can blow bottles in shapes: carbonated, mineral, pesticide, cosmetics, wide-mouth, hot filling, and other packing containers, which is made of plastic of crystalline type, such as PET and PP etc.

1).High Automatization

2).High Intelligence:The machine can be controlled through touch screen and running status is shown on it.

3).High Quanlity:Steady infrared heating system blowing and highly precise blow-mould closing system ensure quality.

4).High Speed:6000BPH(6-cavity), 8000BPH(8-cavity), 12000BPH(12-cavity), 16000BPH(16-cavity).

5).No Contamination:Closed production zone, good self-lubrication system avoid contamination.

6).Low Cost:Low consumption of electricity, air and water.

7).High Transparency:Easy maintenance, absolute safely, visual inspection, low noise.

B.Settings:

a).PLC colour display: MITSUBISHI

b).Pneumatic parts:FESTO(GERMANY)

c).Controller of preform transfer:Servo motor National(JAPAN)

d).Other electric parts are all world-famous brand

C.Machine Features:

C.1. Stable performance with advanced PLC.

C.2. Conveying preforms automatically with conveyor.

C.3. Strong penetrability and good and swift distribution of the heat by letting the bottles rotate by itself and revolute in the rails simultaneously in the infrared preheater.

C.4. High adjustability to enable the preheater to preheat preforms in shapes by adjusting the light tube and the length of the reflecting board in the preheating area, and eternal temperature in the preheater with an automatic thermostatic apparatus.

C.5. High safeties with security automatic-locking apparatus in each mechanical action, which will make the procedures turn into a state of safety in case of a breakdown in certain procedure.

C.6. No contamination and low noise with the air cylinder to drive the action instead of the oil pump.

C.7. Satisfaction with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine.

C.8. Strong clamping force with high pressure and double crank links to lock the mold.

C.9. Two ways of operating: automatic and manual.

C.10. Safe, reliable, and unique design of the position of valve to make the air pressure diagram of the machine easier to understand.

C.11. Low cost, high efficiency, easy operation, easy maintenance, etc, with automatic technological process.

C.12. Contamination is avoided for the bottle body.

C.13. Ideal effect of the chilling with the chilling system.

C.14. Easy installation and starting

C.15. Low rejection rate: less than 0.2 percent.

Blow Molding Machine Picture:

After-sales service

1. We offer you the free machine operation training happened in China.

2. Offering the free testing and installing of the machine in the buyer factory, but the fee of the visa, the ticket, food and living should be in the buyer's charge.

3. The spare parts of the machine and the auxiliary machine can be supply by us.

4. The guarantee of the machine is one year under the normal operation.

5. We offer the customer the technology for free for all life time.

Any question,please call me:

MOB&waspp: +8613915728281

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23