China Artificial Nutrition Fortified Rice Processing Making Machine

Henan Techuang Biotechnology Co., Ltd. / 2022-07-04

- After-sales Service:Overseas Service

- Warranty:One Year

- Type:China Artificial Nutrition Fortified Rice Processi

- Application:Flour, Wheat, Rice flour, China Artificial Nutrition Fortified Rice Processi

- Voltage:Cutomzied

- Appearance:Food Extruder

=== Base Info ===

- Model NO.:LY65 70 75 80 90 110

- Press Materials:Rice

- Press Series:China Artificial Nutrition Fortified Rice Processi

- Condition:New

- Customized:Customized

- Capacity:100-150kg,H 200-250kg,H 300-400kg,H

- Products:Fortified Rice, Nutrition Rice

- Raw Materials:Broken Rice Flour, Wheat Flour etc

- Materials:Food Grade Stainless Steel

- Electric Parts:ABB, Delix, Omron, FUJI or Customized

- Transport Package:Suitable for Shipment

- Specification:Customized

- Trademark:LUERYA

- Origin:Shandong China

- HS Code:84388000

- Production Capacity:30 Sets Per Month

=== Description ===

Basic Info.

Model NO. LY65 70 75 80 90 110 Press Materials Rice Press Series China Artificial Nutrition Fortified Rice Processi Condition New Customized Customized Capacity 100-150kg/H 200-250kg/H 300-400kg/H Products Fortified Rice, Nutrition Rice Raw Materials Broken Rice Flour, Wheat Flour etc Materials Food Grade Stainless Steel Electric Parts ABB, Delix, Omron, FUJI or Customized Transport Package Suitable for Shipment Specification Customized Trademark LUERYA Origin Shandong China HS Code 84388000 Production Capacity 30 Sets Per MonthProduct Description

China Artificial Nutrition Fortified Rice Processing Making MachineArtificial rice processing line introduction

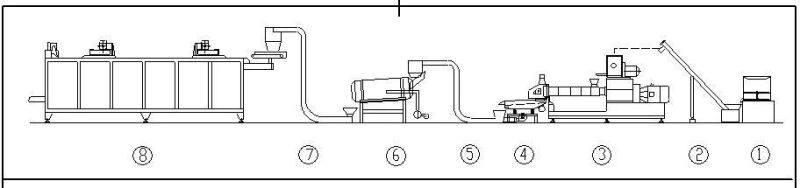

Artificial rice processing line is mainly made up with raw materials treatment system, extrusion system, drying system and controlling system. It has high stability and automatic performance, which offers the possibility to control the expansion of the extruder through various means to control the texture of the final product.

Artificial rice is a new food based on extrusion technology. Adopting rice flour, broken rice (should be milled) as main raw material, artificial rice is made by extrusion and drying processes. Artificial rice has the advantages of great taste, easy-to-cook, strong functionality (such as sugar-free rice, medicinal rice) etc. Right now, more and more consumers and units received artificial rice.

Layout of artificial rice processing line:

raw materials→ extrusion→ screening→ drying→ cooling→ packing

Processing line features

Features of artificial rice processing line

1 High work efficiency, automation degree, materials usage, application range.

2 Low land occupation, power consumption, labor cost, waste rate.

3 Various configurations and capacity choices.

4 Various finished products sizes and shapes.

5 Production factors can be quantified and controlled.

6 World-class food grade fittings.

7 All machines and fittings can be custom-made. ODM or OEM is available.

8 Professional pre-sale, sale and after-sale service.

9 Extruder adopts cooling system to control temperature.

Specification

| Model | LY65 | LY70 |

| capacity | 100-150kg/h | 200-250kg/h |

| Installed power | 85kw | 112kw |

| Actual power | 50kw | 80kw |

Product samples

Company information

Our company( Shandong Luerya )has good experience of the industry development. We have well-experienced managers, outstanding engineers as well as well-trained technical workers. By constant technical exchange with well-known firms of the same line in the world and also by introduction of advanced technique and experience into our company, we have established a strong technical guarantee system. Our company is a one of the most rich experienced manufacturer of puffed extruder and food machinery in China since the year of 1990.

Our Services

1. Pre-sale services:

Act as a good adviser and assistant of clients, enable them to get rich and generous returns on their investments.

1.. Select equipment model;

2.. Design and manufacture products according to clients' special requirement;

3.. Train technical personnel for clients.

2. Services during the sale:

Respect clients, devote ourselves to improving the total value of clients.

1.. Pre-check and accept products ahead of delivery;

2.. Help clients to draft solving plans.

3. After-sale services:

Provide considerate services to minimize clients' worries.

1.. Assist clients to prepare for the first construction scheme;

2.. Install and debug the equipment;

3.. Train the first-line operators;

4.. Examine the equipment;

5.. Take initiative to eliminate the troubles rapidly;

6.. Provide perfect service;

7.. Provide technical exchanging.

FAQ

- Q: Are you a factory or trading company?

A: We are a factory.

2. Q: Could you supply customized machines?

A: We can supply customized machines based on your requirement. By the way, ODM&OEM are available.

3. Q: How long is the warranty period?

A: All of our products have one year warranty.

4. Q:Can you supply oversea service or food formula?

A: Our engineers can serve you in your factory and we can supply formula after ordering our machines.

5. Q: Where are you? How can I get there?

A: We are in Jinan city which is in the North of China, 432km South to Beijing. You can go to Jinan by high speed train or By air directly to Jinan international airport.

6. Q: Have you ever sold your products to International market?

A: Unit 2021 we have sold our machines to more than 60 countries and regions. This number is keeping growing

A: Because of the business scope limitation in China, we can only supply food machines, But we can help you to find the best suppliers in China. As Chinese, we are more familiar with Chinese market.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23