Hot Sale-Forstar High Quality Plastic Flower Pot Injection Molding Machine

Yantai Dianysaw Mfg. Co, . Ltd / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. Flower Pot Machine Computerized Computerized Certification CE, ISO9001:2008 Screw Diameter 80-100 mm Shot Volume 2136-3336 cm3 Shot Weight 1965-3069 g Pressure 233-149 MPa Screw Stroke 425mm Clamping Force 6500 Kn Opening Stroke 920 mm Platen Size 1310 X 1310 mm Space Between Tie Bars 900 X 900 mm Transport Package Export Packing Specification 650ton Trademark FORSTAR Origin China HS Code 8477101090 Production Capacity 400units/YearProduct Description

FORSTAR Injection Moulding Machine (FC, FCE series)

FC, FCE series is a high-end plastic injection moulding machine newly developed by Forstar after uears of R&D and practical experiment. It is developed on the basis of the FST series with introduction of advanced European technique and apperance style. It keeps the advantages of efficiency, precision, energy conservation and stability of FST series while optimized thoroughly.

The features includes,

* Advance Control system

* High Rigidity Platens with T-slots (FC series)

* Extended slides fand friction bells for the moving platen

* Symmetrical Stress Mould Clamping

* Master Lubrication System (FC series)

Technical Characteristics

-CLAMPING UNIT

Symmetrical stress mould clamping

By evenly distributing the clamping force, the platens bear

lower stress which can minimize the instance of platen

distortion,molding problem can thus be reduced.

High Rigidity Platens with T-slot

Machines are equipped with high rigidity T-slot platens which

provides more flexibility and convenience for installation of

different kind of molds, service life of the platen can be

extended comparing with the platen with tap holes.

Extended slides and friction belts for the moving platen

Machines are equipped with extended slides on the moving

platens, which greatly improved the stability of platen

movement during mould opening and clamping. Also, there are

steel friction bells underneath the moving platen, it reduces the

friction coefficient and thus improves the stability and precision

of the platen movement, as well as protecting the mould.

Low pressure mould protection

Master Lubrication System

Tie bars and toggles are lubricated by a master automatic thin oil

lubrication system which distributes thin oil automatically. The

mould adjusting mechanism is lubricated by a manual master grease lubrication system(FC series only),both systems guarantee lubrication efficiency and thus improves reliability and stability of the machine.

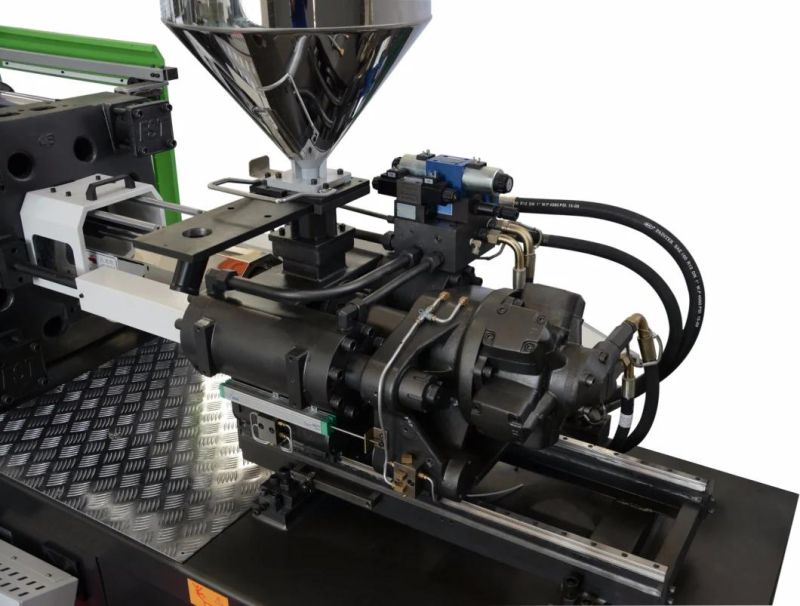

-INJECTION UNIT

Unique double linear guide tracks

The injection unit is equipped with double linear guide tracks which improves the injection accuracy and stability. With matrix high rigidity supporting base, the double linear guide tracks guarantee high stability of the whole injection unit.

High-efficiency screw and barrel

Screws with special design works perfectly during plasticizing providing excellent color mixing effect, can satisfies customer's different requirement on the products. The injection features also goes with a high rigidity nozzle and nozzle flange, these two parts together with the special designed screw head, check ring and check seat effectively guarantee higher repeatability as well as ensuring production effect.

General Safety features

These features include nozzle purge guard, fully covered barrel, movable sliding hopper and centrallubrication system. They not only guarantee safe

machine operation but also higher production efficiency.

-HYDRALIC UNIT

FC series is a combine of servo closed-loop system and variable pump technique used in Forstar for many years. Forstar made overall improvement and optimization on selecting motors, oil pumps and tubes. This greatly improves stability, reliability of the machine, ensuring its high-efficiency, energy saving, durability and low-noise operation.

The variable pump series goes with a high performance load-sensitive variable displacement pump, which alone saves 30% to 50% of energy consumption.

The servo series is equipped with advanced servo system, saving as much as 40% to 80% of energy consumption.

The injection manifold is relocated on the top of the injection cylinders, so is the clamping manifold on the clamping cylinder. This design enables faster responses and greatly increase the injection and clamping accuracy.

The oil tank is sealed with imported two-piece sealing elements such as Hallite which works better than traditional back-to-back sealing.

The layout of oil tubes and oil dripping tray are redesigned and optimized to make sure the cleanness of plastic products and the production site.

-CONTROL UNIT

Equipped with professional European KEBA computer to guarantee the production stability and efficiency.

Multi-stage PID barrel temperature control, non-volatile memory, oil-temperature monitoring.

Mould opening and clamping, injection, and pre-plasticizing are all monitored by high precision linear transducer (accuracy can be as high as 0.1mm) ensuring fast response and high stability of the control system.

More than 500 molds data storage.

Computer hardware self-detect alarm function.

Digital and curve statistic display for injection end.

Pre-heat function.

Supports remote monitoring.

Related Production Field

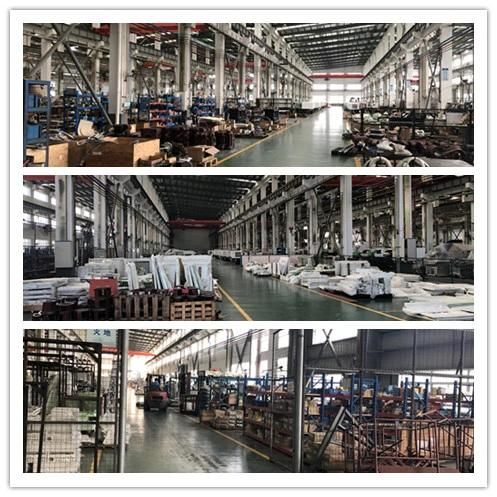

Our Factory

Latest Information--2019

Our Services & Other

1. Reply the email and take action in 24 hours.

2.100% Quality inspection before the shipment.

4. Auxiliary machines for complete line.

5. Customized design as requirements

6.1 Years garantee

7.Provide permanent after-sales service inquiry

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23