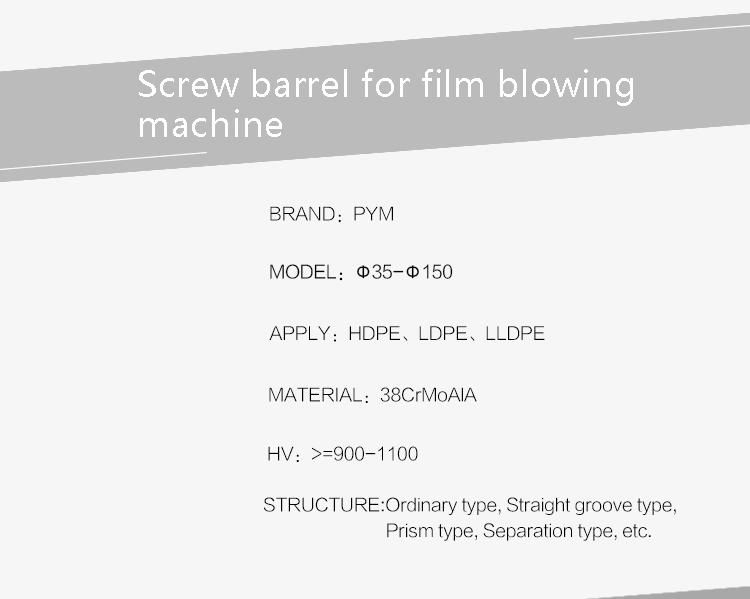

Screw Barrel for Blow Moulding Machine

Wenzhou Handpack Machinery Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. 65mm Brand Name Pym Model Number Screw and Barrel Base Material 38crmoala; SKD11; SKD61; 40cr; 42CrMo; High Qualit Screw Diameter 20-500mm L/D Ratio 10-50 Bimetallic Fe-Based,Ni-Based,Tungsten Carbide Bimetallic Screw Process Spray Welding Bimetallic Barrel Process Centrifuge Casting Screw Design Single Screw,Twin Screw Transport Package Wood Box Specification CE SGS BV TUV Trademark pym Origin Zhejiang Ruian HS Code 84779000 Production Capacity 1000/MonthProduct Description

The main advantage of screw barrel:

A. Advanced Nitriding Technology

B. Anti-corrosion and Wear-resisting Duplex Metal Spraying Technoloy

C. We uses special alloy powders being sprayed and welded on the screw's ridge, and uses different alloy and welding methods for the screw of different functions.

Remarks: We can design and manufacture various kinds of screw barrels according to the customer's requirement.

Technological Process:

Blanking---RoughMachining---Quenching & Tempering ---Semi Finishing Machining---Finished Product---DetectingNitring/Alloy Processed--- Finish Machining

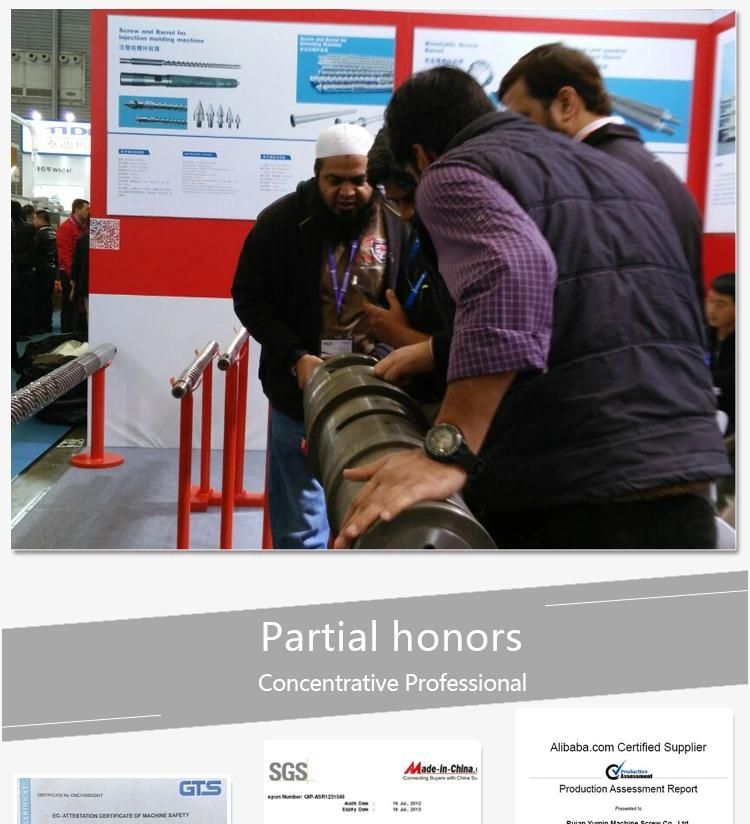

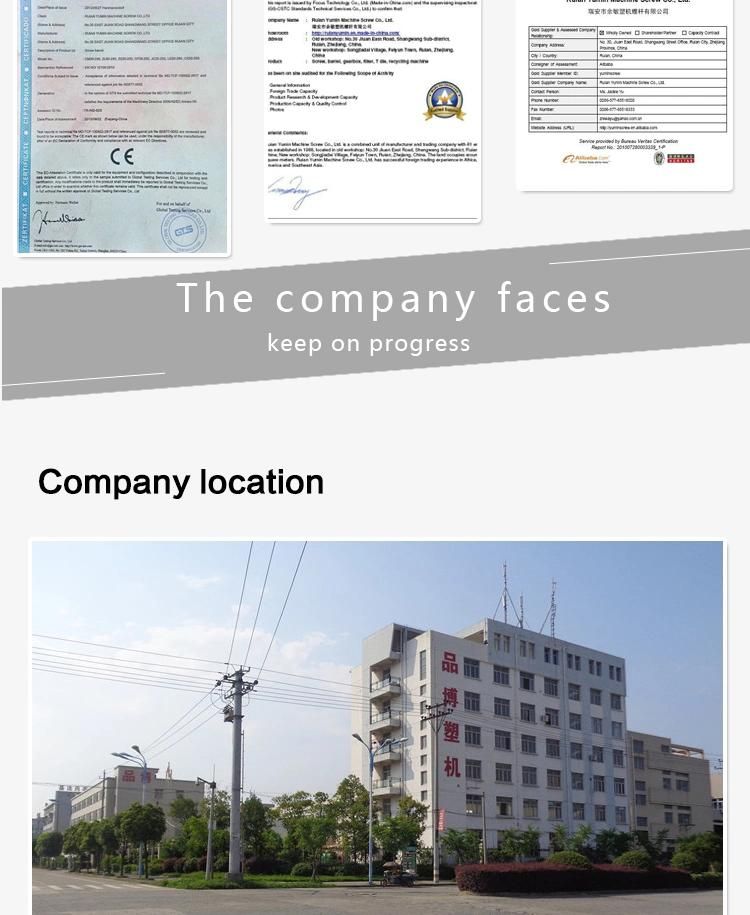

About us:

Ruian yumin machine screw co., ltd is a factory specialized in making screw barrel, gearbox ZLYJ series, t die, filter and extruder machine. Founded in 1988, it has become the biggest supplier of main parts in Ruian city which is basement for plastic machine. Is its brand name. Comparing with other manufacturers, it has its great advantages as followings:

A> long time experience and history screw barrel for shoes machine

B> long time nitriding treatment and heating treatment by itself extruder screw and barrel / vent screw barrel for pvc

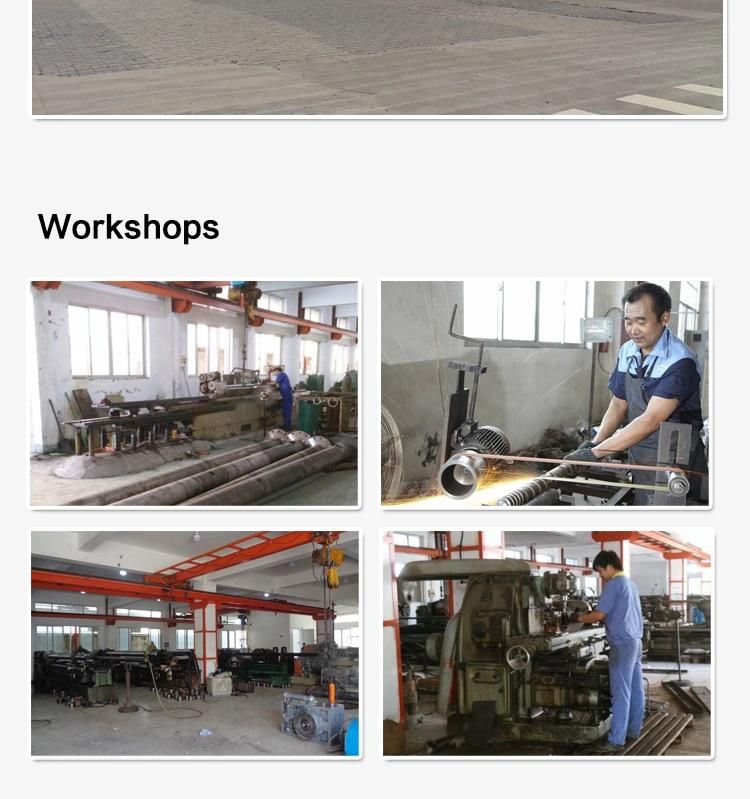

C>advanced Fanuk series CNC computer-controlled milling machines

D>depth hole drilling machine in 10meters length, which ensure the straigtnss of barrel inside.

E> CAD drawing confirmation before start making

F> Prompt after sale service

G>Land owner and registration capital 25, 000, 000RMB

Why choose us:

1. We have long history and experience working in the field

2. We have the most advanced equipments and technique in our industry

3. We have professional engineers and staffs

4. We have 100% quality ensure system and 24hours after-sale service system

5. We own two lands of workshop, covering 5000cbms.

Our serivices

I Want to express my thanks to all my dear clients~~~~~~Thank you for visiting our website and glad to see you.

Anyone won't buy any products from strangers until they know each other better, but it's a long time for you to understand a strange supplier well, then how you can find a best supplier during so many factories is a problem! Cathy believe that every customer is the turning point of her life, she is very gald to make friends and do business with you, if you trust her so much, just give each other an opportunity to know each other better!

Thank you so much! !

Your dear Cathy

Welcome any of your inquiry about the goods you are interested in and greatly appreciate any comments or suggestions. More details, pls feel free to contact us.

| Base Material | 1)38CrMoAlA(JIS SACM645) 2)Cr12MOV(JIS SKD-11) 3)4Cr5MoSiV1(JIS SKD-61) 4)42CrMo(AISI 4140) 5)9Cr18MoV |

| Bimetallic Alloy Materials | 1)Fe-based alloy 2)Ni-based alloy/Deloro alloy 3)Co-based alloy 4)NiCo-based alloy 5)Tungsten carbide/Wolfram carbide |

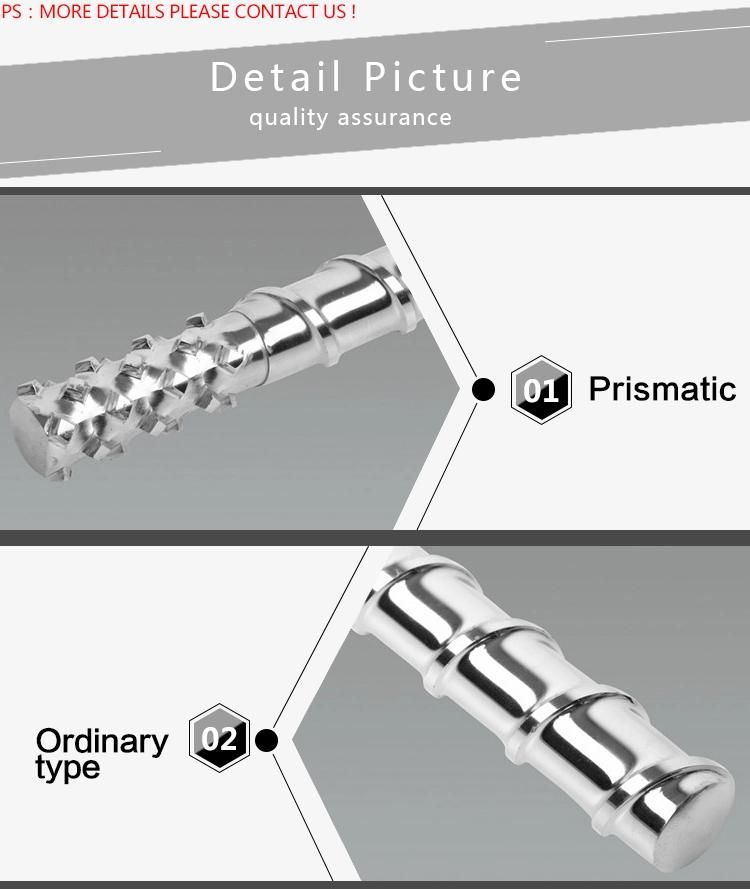

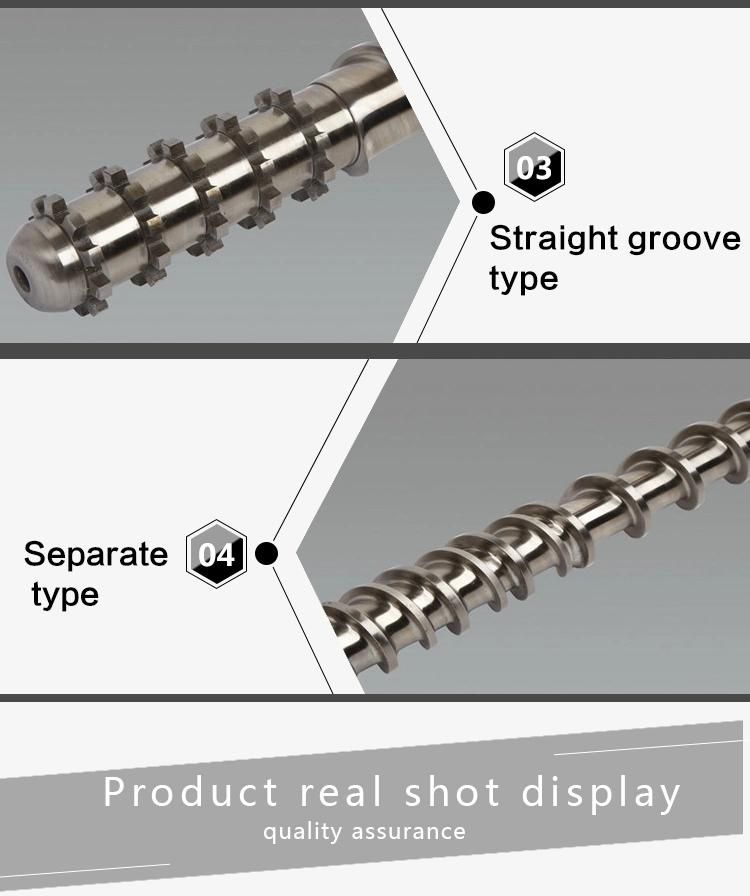

| Designing | Screw structure and compression ratio can be designed according to different products & different clamping force requirement. |

| Treatment Technology | 1)Longer time Gas Nitriding treatment 2)special anti-wear & abrasion alloy (bimetallic) 3)tungsten carbide 4)cobalt base alloy 5)stainless steel 6)Gh113 nickel based alloy Treatment Nitriding treatment(>100 Hours) Depth of Nitrided Layer: 0.5-0.8 mm Hardness of Nitrided Layer: >950Hv Hard Chrome Plating treatment: Thickness of Hard Chrome Plating Layer: 0.03-0.06mm Hardness of Hard Chrome Plating Layer: ≥950HV Nickel alloy plating.treatment: Bimetallic Barrel Centrifugal Casting (Inlay Alloy) Bimetallic Screw: Plasma Alloy Coating Spraying Depth of Bimetallic Layer: >2mm Hardness of Bimetallic Layer: HRC 62-72 |

| Material Application | 1)General Plastics 2)ABS,PA,PC,PE,PET,PP,PS,EVA,PU,PVC,U-PVC,etc 3)PA + GF(Glass Fiber) 4)Flame-resistant Reinforced Plastics 5)Modified Engineering Plastics 6)All kinds of Mixed Recycled Material(in Scrap or Granule),etc |

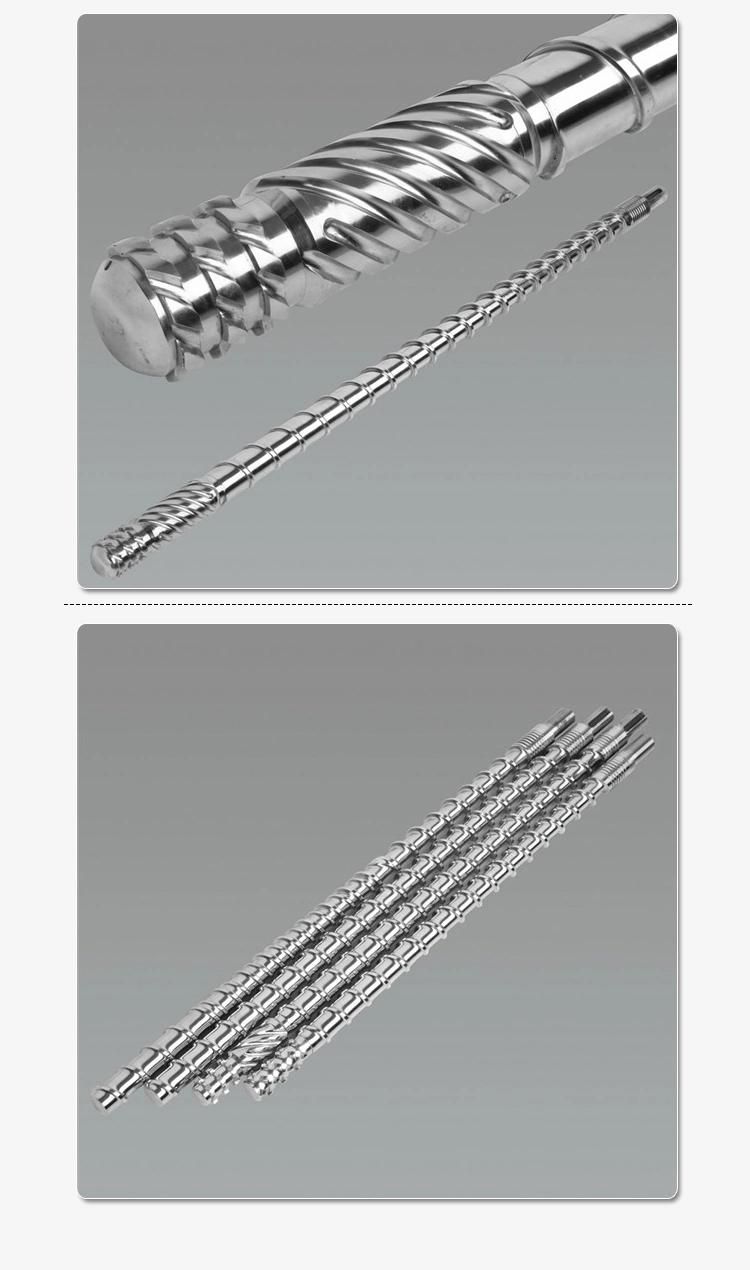

| Basic Infomation | L/D =10-50 Screw Diameter: Φ20-Φ500mm Surface Roughness :Ra0.4um Linearity of the screw: ≤0.015mm Linear axis limit: ≤0.02mm Nitriding treatment, surface hardness: HV≥900-1000 Fragility of Nitration:≤Two grade |

| Warranty period | 2-4years(Depends on the plastic raw materials) Bimetallic: much longer lifetime. |

| Competitive Edge | 1 .Long lifetime,low energy consumption. 2. Wonderful plasticizing 3. Top-quality bimetallic screw and barrel 4. High wear resistance, resistance to corrosion 5. Fast and On time delivery 6. Best customer after-sale service! |

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23