PP PE Film Plastic Recycling Granulator Machine

Fujian Quanzhou Huazuan Diamond Tools Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. SJ80/156 Customized Customized Certification CE, ISO9001:2008 Condition New Transport Package Standard Wooden/Film Package Specification 200-2000kg/hour Trademark ACEMIEN Origin China HS Code 8477209000 Production Capacity 200-2000kg/HourProduct Description

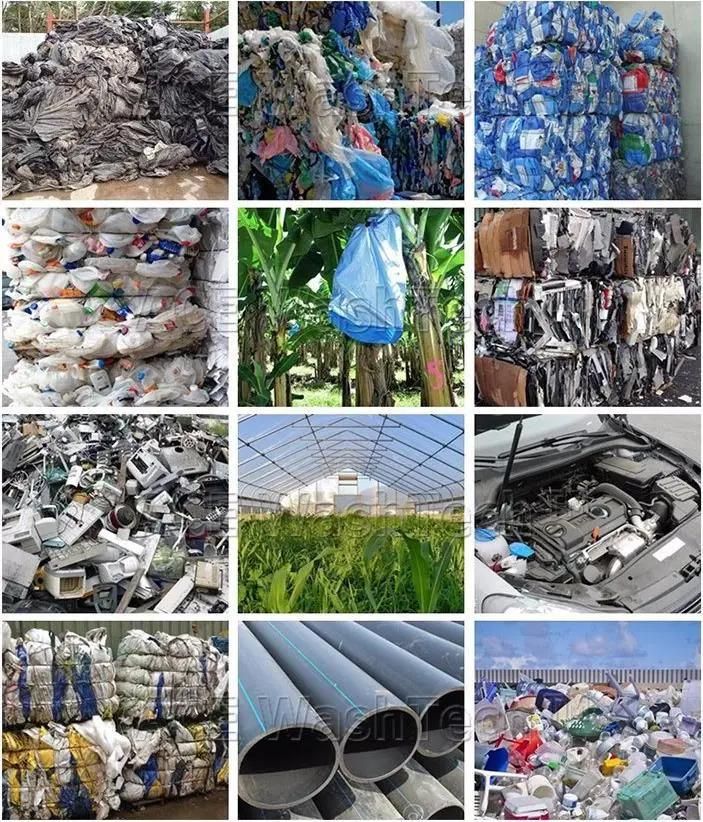

Used pp woven bags granulating making machine/pe plastic film pelletizing machine1.PE PP film recycling granulating machine is special equipment for the PE PP film recycling granulating, it equipped with compacting machine which could pre- compact the film into smaller granules, it is easily to feed into screw barrel of extruder. It also can improve production capacity and save labour cost.

2. Extruder barrel have two vacuum exhuast mouth which can fully remove the moisture and hence the final granule quality will be very perfect.

3. This line adopt water cooling pelletizing

Detailed description of Used pp woven bags granulating making machine/pe plastic film pelletizing machine

1. Conveyor:Conveyor plastic film/woven bags into compactor machine

2. Plastic Compactor:crushing and compactor plastic film/wocen bags

3. Extruder system:plasticizing material and exhausting gas.

4. High speed Net exchanging system and Die-head:filter material impurity and extruder noodle

5. Water cooling tank:cooling extruder noodle

6. Pelletizer:cut noodle

7. Vibration sieve:remove bad pellet and keep good pellet.

8. Air Blower:convey good pellets into silo.

9. Storage silo:collect pellet

Packaging & Shipping

1.For the loose cargo we will packing by wooden box

2.For the full container loading we are packing the machine by film and some on pallet accordingly

3.We can shipping the goods by air or by sea

4.We will send pictures of cargo loading to our client to check and keep recording

5.We can send cargo to client's warehouse to loading

Our Services

1.Pre-sale: we given client the details technician offer, sign the sales contract etc

2.In-sales: we supply the details layout, installation instruction, technician support for the clients

3.After sales: we arrange engineer to install the machinery and training the workers for client

4.We have 24hours team to solve the after sales problem

5.We have free spare parts with the machine

6.We supply long term spare parts for every customer

7.We always up date the new technology to every customer

FAQ

1.How to Choose proper Products you want?

Please tell us as detail as what you want

What's your raw material it is

What's the final products you want to produce

What capacity you want it performance

2.How to Control the quality?

We have technical, engineer team design the sample machinery before enter into market

Production QC team ensure the machine manufacturing quality

We will running every machine after finished before shipment

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23