Complete Kiwi Fruit Powder Production Plant

Jiangyin Yiran International Trading Co., Ltd. / 2022-07-05

- Type:Dryer

- Voltage:380V

- Power:Custom

- Customized:Customized

- 100-2000kg/H:Turnkey Project

- Delivery:60days

=== Base Info ===

- Model NO.:GY-NZ1

- Transport Package:Container

- Specification:as customer capacity

- Trademark:GENYOND

- Origin:China

- HS Code:84386000

- Production Capacity:1000sets,Year

=== Description ===

Basic Info.

Model NO. GY-NZ1 Transport Package Container Specification as customer capacity Trademark GENYOND Origin China HS Code 84386000 Production Capacity 1000sets/YearProduct Description

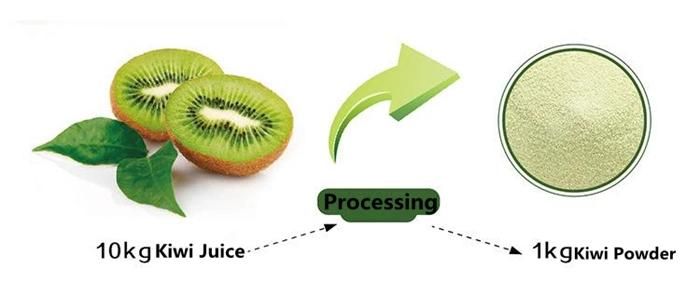

Complete Whole Kiwi Fruit Powder Production and Packing Line

Production line mainly includes these parts:

A. Fresh fig receiving system

B. Washing and sorting system

C. Crushing and refining system

D. Concentration and evaporation system

E. Sterilization system

F. Drying system

G. Cooling

H. Filling and packing

The equipment is suitable for Making Kiwi Fruit Powder ,

Most of this machine is made of stainless steel,simple to operate and maintenance,

and also we can modify the machines according to your requirements

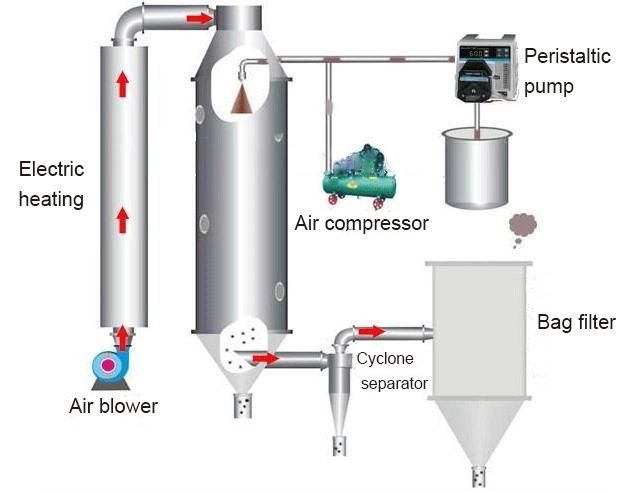

Spray drying process is the widest used in the liquid forming process and in drying industry.

The drying technology is most suitable for powder, particle products from materials, such as,solution, emulsion,

SC and pumpable paste states material. For this reason, when the particle size and distribution of the final product,

their residual water contents, the stacking density and particle shape must meet the precision standard,

spray drying process is one of the most desired processes.

After filtering and heating, the air enters into air distributor on top of the Drying Equipment.

The hot air enters into the drying tower spiral form and uniformly.

By .passing through high-speed centrifugal atomizer on top of tower, the material liquid will rotate and be sprayed

into the extremely fine mist liquid beads. Through the very short time of contacting with heating air, the material

can be dried into final products. The final products will be discharged continuously from the bottom of drying tower

and from cyclone separator.The waste gas will be discharged from exhaust fan.

Atomizer is the most important accessory in spray drying machine, it is used for changing LIQUID status into

SPRAY status at a high speed rotation motions, usually can reach 18000~25000 rpm, Our company has adopt

Chinese Specilalzied Supplier, can ensure customers for 2 years warranty period.

At a high speed of drying, after spraying of the material liquid, the surface area will be increased greatly.

In the hot air flow, 95%-98% of water can be evaporated at a moment. The time of completing the drying

needs only several seconds.

This is especially suitable for drying the heat sensitive materials. Its final products own good uniformity,

mobility, dissolving capacity. And the final products are high in their purity and good in their quality.

The production procedures are simple and the operation and control are easy.

The liquid with the moisture contents 40-60% (for special materials, the contents may reach 90%) can be dried

into the powder of particle products for one time. After drying, there is no need for crushing and sieving, so as

to reduce operation procedures in the production and to enhance product purity. The product particle diameters,

looseness and water contents can be adjusted through changing the operation condition in a certain scope.

It is very convenient to carry out control and management.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23