Automatic Chocolate Production Line with Siemens PLC Control Tpx

SHANTOU DAFU PLASTIC PRODUCTS FACTORY CO., LTD. / 2022-07-05

- Certification:CE, ISO9001

- Power Source:Electric

- Process:Thermal Processing

- Automatic Grade:Automatic

- Application:Candy, Chocolate, Popcorn, Chips, Donut, Candy Bar

- Customized:Customized

=== Base Info ===

- Warranty:1 Year

- Model NO.:TPX

- Voltage:Customize

- Dimenssion:Various

- Function:Bar Production Line

- Cooling Tunnel Temp:5-10

- Turnning:Selectifve

- Enrober:Selectifve

- Raw Material:Stainless Steel

- Certificate:Ce; ISO9001

- Line Length:According to Customer′s Workshop

- Transport Package:Wooden Box

- Specification:customized

- Trademark:Gusu

- Origin:Suzhou

- HS Code:8438200000

- Production Capacity:500 Unit,Units Per Month for Bar Making Machine

=== Description ===

Basic Info.

Model NO. TPX Warranty 1 Year Voltage Customize Dimenssion Various Function Bar Production Line Cooling Tunnel Temp 5-10 Turnning Selectifve Enrober Selectifve Raw Material Stainless Steel Certificate Ce; ISO9001 Line Length According to Customer′s Workshop Transport Package Wooden Box Specification customized Trademark Gusu Origin Suzhou HS Code 8438200000 Production Capacity 500 Unit/Units Per Month for Bar Making MachineProduct Description

Candy Bar Cereal Bar Energy Bar Production LineProduct Description

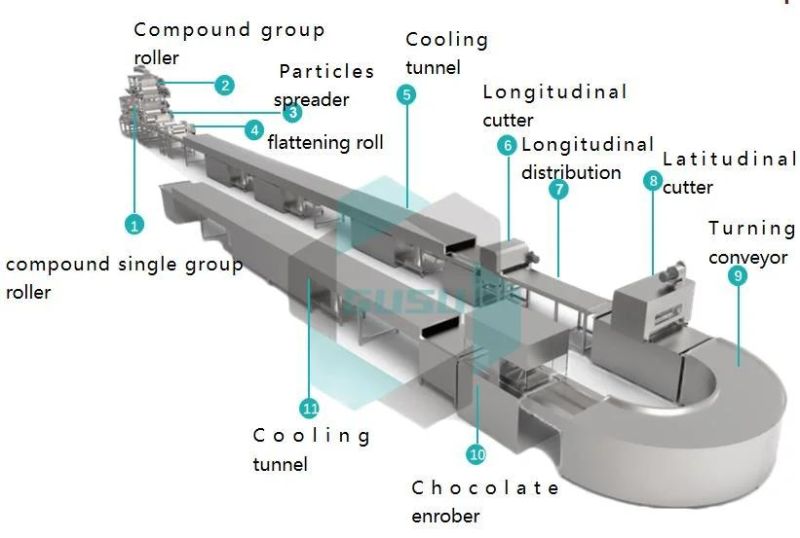

TPX series of candy bar line is design to mix boiled syrup, powder, grain, etc, through pre-cooling, to form the uniform thickness and width, then cut into blocks or bars by longitudinal and latitudinal cutter, then transport to Enrober to coat the product surface with a layer of chocolate; Create a unique bars.

Features:

1) Application: energy bar, protein bar, fruit bar, nougat, Snickers, Sachima, etc.

2) Model: Gusu candy bar is available in five widths: 200,300,400,600 and 800 mm. All functions of the forming line can be controlled by one or two PLC control cabinets.

3)All the equipment is manufactured to be extremely robust and reliable.

4)The machinery is almost full stainless steel construction for maximum hygiene and simple cleaning down.

Techinical Parameters

| Model | Single Group Roller Width(mm) | Compound Group Roller Width(mm) | Flatten Roller Width(mm) | Roller Temp.(ºC) |

| TPX200 | 150-200 | 150-200 | 150-200 | -20~-70 |

| TPX300 | 280-330 | 280-330 | 280-330 | -20~-70 |

| TPX400 | 380-430 | 380-430 | 380-430 | -20~-70 |

| TPX600 | 580-630 | 580-630 | 580-630 | -20~-70 |

| TPX800 | 780-830 | 780-830 | 780-830 | -20~-70 |

Components:

- Compound Single Group Roller

- Compound Group Roller

- Particle Spreader

- Former Roller

- Cooling Tunnel

- Longitudinal Cutter

- Longitudinal Distribution

- Latitudinal Cutter

- Chocolate enrober(Selective)

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23