Lightweld 1500 Laser Welding System 2000W Hand Held Laser Welding Machine Aluminum Steel

Emoer Industry Limited / 2022-06-23

- After-sales Service:Provided

- Warranty:1 Year

- Application:Electronic Industry, Automotive Industry, Manufacturing Industry

- Technical Class:Pulse Laser

- Control:Automatic

- Power Density:Deep Fusion Welding

=== Base Info ===

- Model NO.:HJZ-1000-HWD

- Laser Classification:Optical Fiber Laser

- Type:Portable Welding Machine

- Package:Export Sea-Worthy Packing or Air-Worthy Packing

- Electrical Source:220V,50Hz,40A

- Positioning:Red Light

- Power Consumed:Less Than 9kw

- Laser Power:1000W

- Product Name:Laser Spot Welding Machine

- Cooling System:Water Cooling

- Name:Laser Welding Machine

- Working Mode:Continuous

- Power Range:10-100%

- Weight:Approximately 300kg

- Size:600X930X1050mm

- Laser Focus:F=200mm

- Power Supply:380-420V

- Transport Package:Export Sea-Worthy Packing or Air-Worthy Packing

- Specification:1650X1250X1050MM

- Trademark:HJZ

- Origin:Wuhan, China

- HS Code:8515809090

- Production Capacity:100sets,Month

=== Description ===

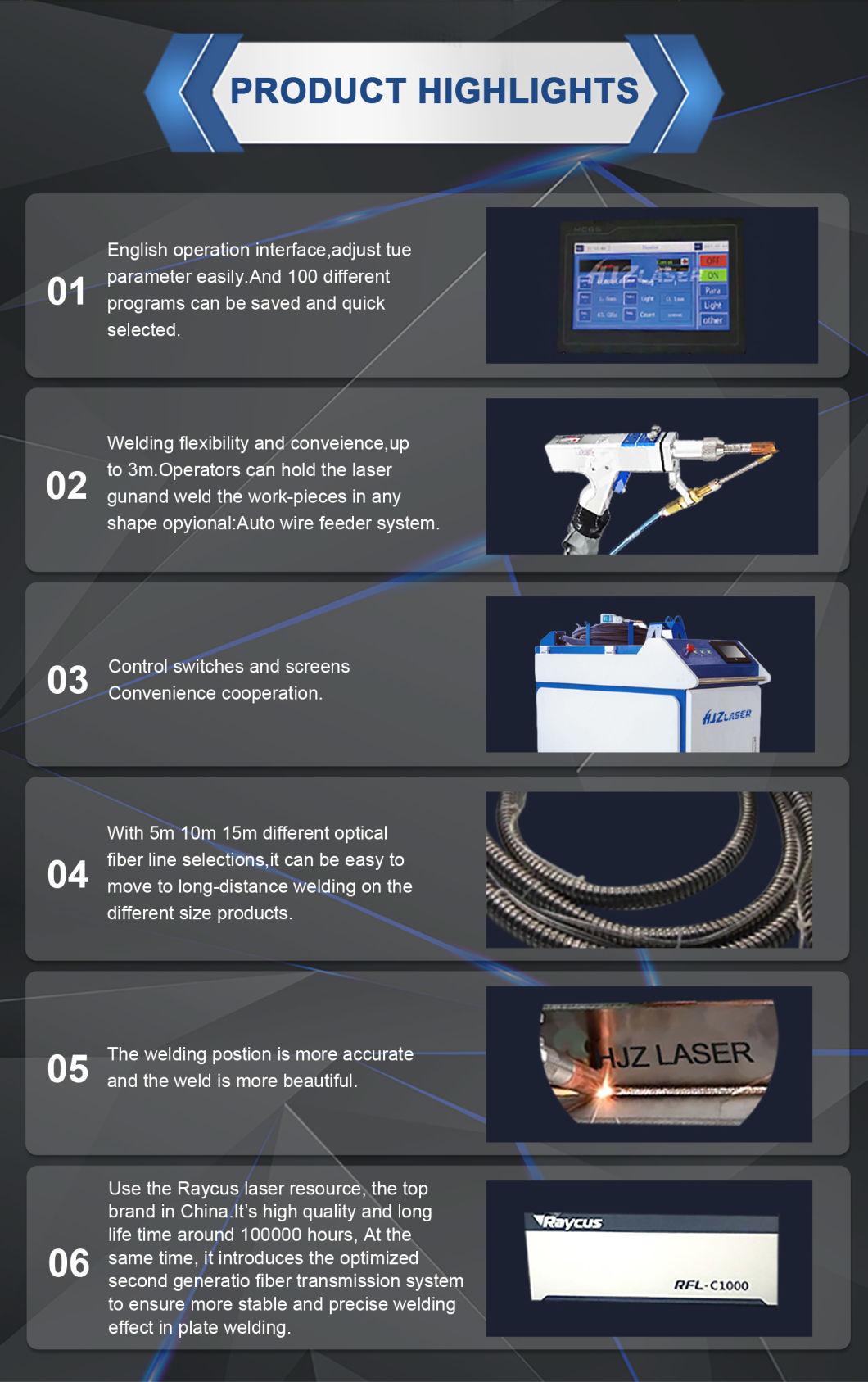

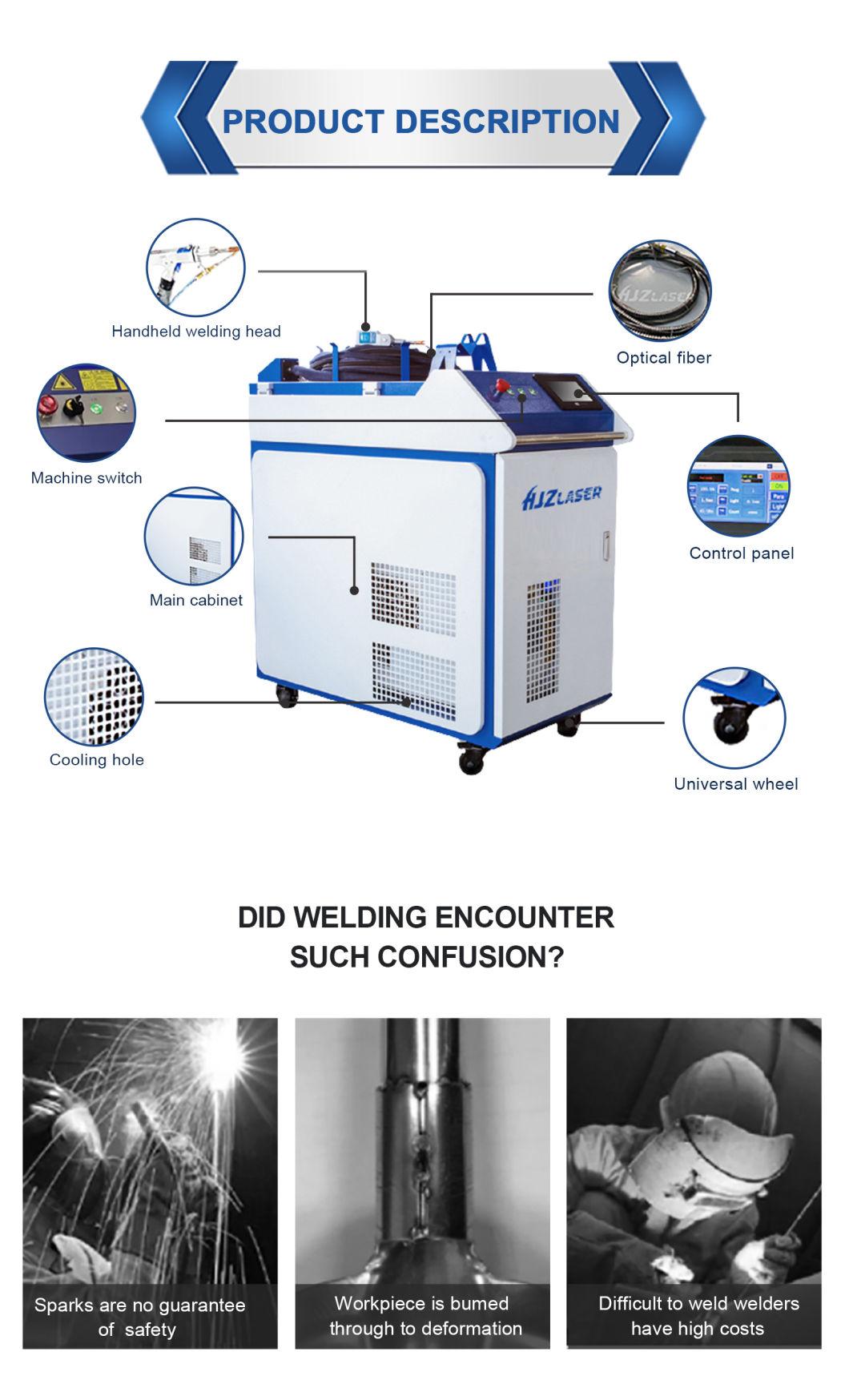

Handheld Fiber laser Welding Machine

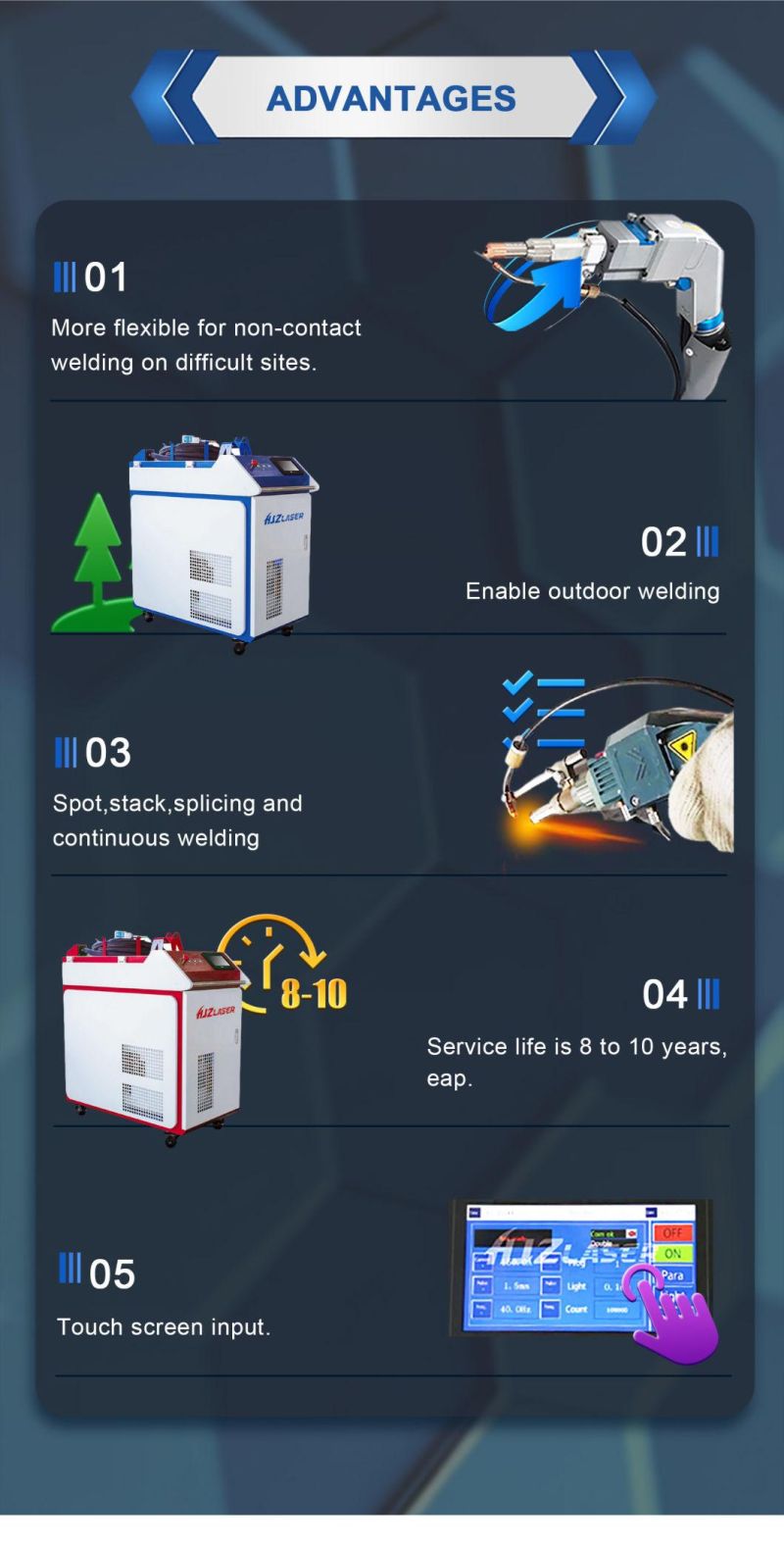

Advantages:

1. The laser welding machine adopts 1000 watt fiber laser, which has high photoelectric conversion efficiency and long life of 100, 000 hours. The energy provided by electric energy is 25%-30% converted into laser energy, and the photoelectric conversion rate is many times than that of YAG laser.

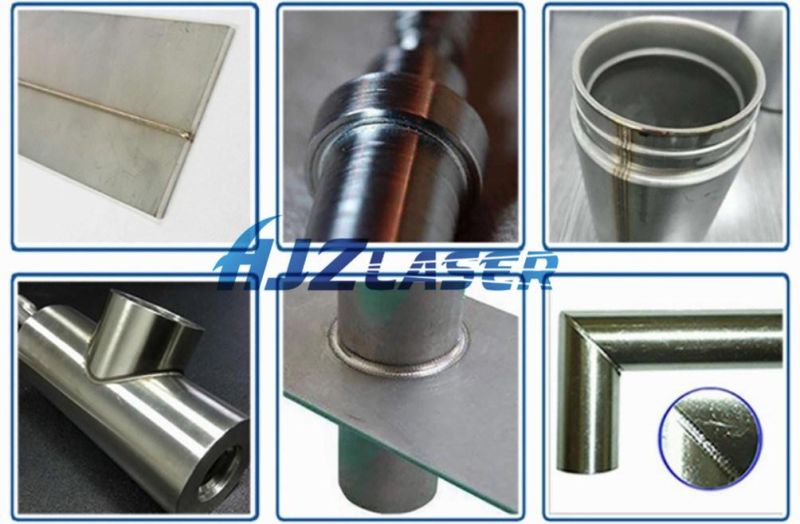

2. The energy density is high, the heat input is low, the amount of thermal deformation is small, and the melting zone and the heat-affected zone are narrow and deep.

3. High cooling rate, which can weld fine weld structure and good joint performance.

4. Compared with contact welding, laser welding eliminates the need for electrodes, reducing daily maintenance costs and greatly increasing work efficiency.

5. The weld seam is thin, the penetration depth is large, the taper is small, the precision is high, the appearance is smooth, flat and beautiful.

6. No consumables, small size, flexible processing, low operating and maintenance costs.

7. The laser is transmitted through fiber optics and can be used in conjunction with a pipeline or robot.

Application:

It is widely used in the automotive, machinery manufacturing, medical equipment, shipbuilding, chemical industry, aerospace, aviation, power battery and daily necessities industries.

Configuration:

Product advantages:

The laser welding machine adopts 150-3000 watt fiber laser source, which has high photoelectric conversion efficiency and long life of 100,000 hours. The energy provided by electric energy is 25%-30% converted into laser energy, and the photoelectric conversion rate is many times that of YAG laser.

Application areas:

It is widely used in the automotive, machinery manufacturing, medical equipment, shipbuilding, chemical industry, aerospace, aviation, power battery and daily necessities industries.

Pre-sale service:

1) According to customers demands, provide relevant technical guidance.

2) Assist customers to design and make laser engraving/cutting solutions considering technical feasibility.

3) Provide equipment demonstration for customers to investigate, make samples and do test, etc.

After-sale service:

1) 1 year warranty for laser metal cutting machine;

2) Offer lifelong repair;

3) Engineers available to service machinery overseas.

4) Multi language service;

5) Offer 24 - hour technical support.

Training can be processed in the following ways:

1) Workers of customers can come to our factory in Wuhan, China to get the most professional hand-by-hand training.

2) We can send engineers to customers' country and do training for workers in customers' target factory. However, tickets and daily consumption like food and accommodation should be afforded by customers.

3) Remote training through Internet tools like Team-viewer, Skype and other instant communication software.

Guarantee:

We offer free Two-year warranty and durable maintenance&repair support for the purchased machines. Within the warranty time, we are responsible for the cost-free repair once the equipment fail or the machines break down(except human factor and force majeure causes) and we shall offer the replacement parts for free(except consumed parts). During the non-warranty time, we just charge the flat cost based on actual cost of repair.

About HJZ Laser:

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23