PE/PP Plastic Processed and Single Screw Extruding Machine for Making16-630mm Pipes

Shanghai Ace Superhard Tool Co., Ltd / 2022-07-04

=== Base Info ===

=== Description ===

Configuration:

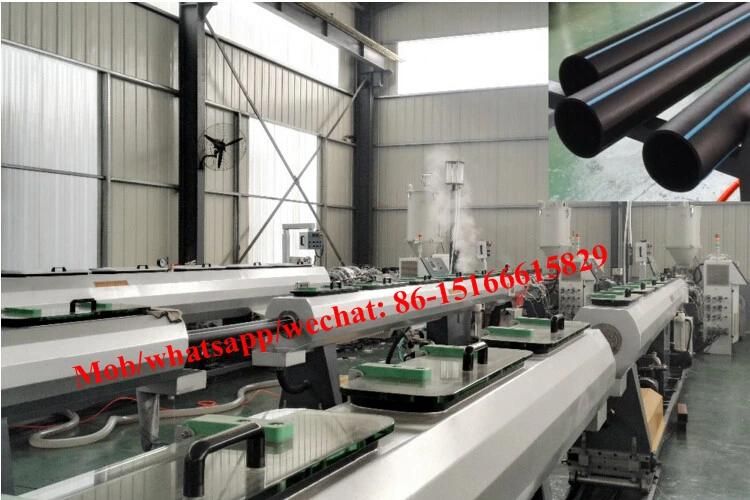

Plastic automatic loader →Hopper plastic dryer→ Single screw extruder (Mark line extruder)→ Mould and calibrator → Vacuum forming machine → Water cooling tank → Haul off machine → Cutting machine → stacker

III. MAIN FEATURES:

- extruder: adopting conical twin-screw extruder, unique designed screw, realizing shorting plasticizing time, good compounding and excellent plasticization.

- gearbox: adopting super quality gear box and reducer, with nice outline, stable running, low noise and long service time.

- extruding barrel temperature controlling system: adopting cast aluminum heaters with stainless steel covers, wind cooling system, ensuring good features of cooling and heating, precision temperature controlling.

- screw and barrel: screw-core installing with internal temperature controlling system, barrel equipped with vacuum degassing system, can get rid of the waste gas from the raw material which can guarantee super quality of the products.

- driving system: adopting A.C motor, using FUJI or ABB inverters which provide stable torque output and various speed.

- vacuum calibrating tank: with two vacuum chambers which can make sure the perfect roundness of the pipe, spraying water cooling, equipped with temperature controller, realizing automatic discharging the water, the main body of the tank make of stainless steel, long service time.

- haul-off machines: 2 laws, 3 claws, 4 claws, 6 claws and 8 claws are provided to manufacture various pipes, haul-off speed governed by the FUJI or ABB inverter.

- cutting unit: saw cutting and planet saw cutting, with dust collection system.

- stacking unit: automatic overturning system, can freely fix the length of the pipe.

- controlling system: manual controlling cabinet or SIEMENS PLC touch screen controlling

IV. MAIN APPLICATION:

- 1. Water supply and drainage pipelines in building;

- 2. Rainwater drainage pipelines in building;

- 3. Electrical wiring pipe in building;

- 4. Air conditioning condensate water systems.

V. MACHINE PICTURES:

V. Our service of PE PIPE Extrusion Line/ Extrusion Machine / Making Machine /Extruder

1.Before order: We will provide relevant information on various technology and business consulted by customers. If clients want to visit our company, we will offer all they need for convenience.

2.During order: company designs groundsill installation chart for water, electricity and gas of equipment basing on real condition and customers' requirements and provides detail order list and matching manufacturer for reference for customer.

After equipment arrival, our service personnel will arrive at posted locale for installation, debugging, training and technology transfer till customers can operate independently and manufactures eligible product. Service personnel have to arrive at customer's locale in time when we provide service for client again.

3. After order: we will offer 12months after sales service freely, but our service will be life-long. if some parts are broken, we will send them by express, air or ship as soon as we can.

VI. COMPANY INFORMATION

QINGDAO JINFUXIN PLASTIC MACHINERY CO., LTD is one professional plastic extrusion machinery factory with 20 years experience. it is located in QINGDAO, China.

Besides HDPE single wall corrugated pipes production, it is a specialized importing & exporting company mainly engaged in all kinds of goods and technology. The company is committed to provide full-service, create a one-stop platform for the international trade and provide a one-stop import & export agency service including the global goods shopping guide, international logistics and import & export clearance for all kinds of enterprises and public institutions and individual. The company has maintained a very good cooperative relationship with dozens of the customs, commodity inspection institutions and freight forwarders at the coastal and inland ports, with its business scope covers more than 80 nations and regions all over the world.

The company has a very professional international trade operating team, equipped with professional customs clearance, inspection, storage and transportation and BIS staff. All the department managers have more than five years experience in the international trade field. The proportion of the workers who have got the college degree or above is up tor 90% among the company employees. The company has established long term and stable business relationship with many customers at home and abroad.

Qingdao JINFUXIN Plastic Machinery Co,. LTD warmly welcome customers at home and abroad from different fields to establish business relationship and create win-win situation.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23