Copra Oil Extraction Production Line

Qingdao Enka Industrial Co., Ltd. / 2022-07-05

- Type:Full Line Machine

- Application:Coconut

- Voltage:380V

- Appearance:Vertical

- Press Materials:Coconut

- Press Series:Second

=== Base Info ===

- Model NO.:CVO

- Condition:New

- Customized:Customized

- Transport Package:Wooden Case

- Specification:material: stainless steel

- Trademark:Reyes

- Origin:China

- Production Capacity:500set,Year

=== Description ===

Basic Info.

Model NO. CVO Condition New Customized Customized Transport Package Wooden Case Specification material: stainless steel Trademark Reyes Origin China Production Capacity 500set/YearProduct Description

Coconut is a tropical woody oil plant of the Palmae. Copra can be produced through drying the coconut flesh. When the moisture content of copra reduces to 6% - 10%, it contains the copra fat of 57% - 75%. Traditional press method can be used to extract coconut oil and the coconut cake produced after extraction can be used as animal feed. Coconut flesh can also be processed into coconut powder, dried coconut and other food.

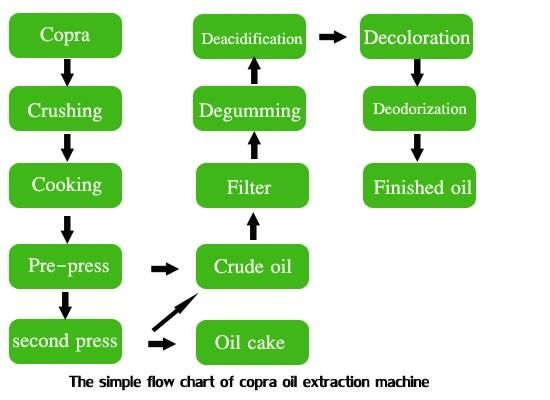

Pretreatment process:

Copra→cleaning→crushing→steaming and frying→ pre-pressing→ twice pressing→crude oil

Refining process:

Crude oil of copra→ filtering→ phosphoric acid degumming→deacidification→decolorization→deodorization→refined oil product

Coconut oil extraction production line mainly includes crushing section, steaming and stir frying section, extracting section, degumming section, deacidification section, decoloration section and deodorization section.

Copra moisture: it should be controlled in 7%-10%, otherwise it is not conducive to oil extraction.

Coconut oil extraction production line of Henan Huatai Cereals and Oils Machinery Co., Ltd. has the following advantages:1.With low energy consumption and long service life to maximize the profit of customers;

2.To minimize the loss of oil, improve oil yield, improve production quality and improve the quality of oil and meal.

copra oil extraction production line has the following advantages:

1, relatively low energy consumption, long service life, can be the greatest possible for customers to create profits;

2, to minimize the loss of coconut oil, increase the oil yield, improve production quality, improve the quality of coconut oil and meal.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23