PP/PE Waste Plastic Granules Pellet Machine for Recycling Granulator Price/Waste Plastic ...

ShunDe Jiatian Hard Tool Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

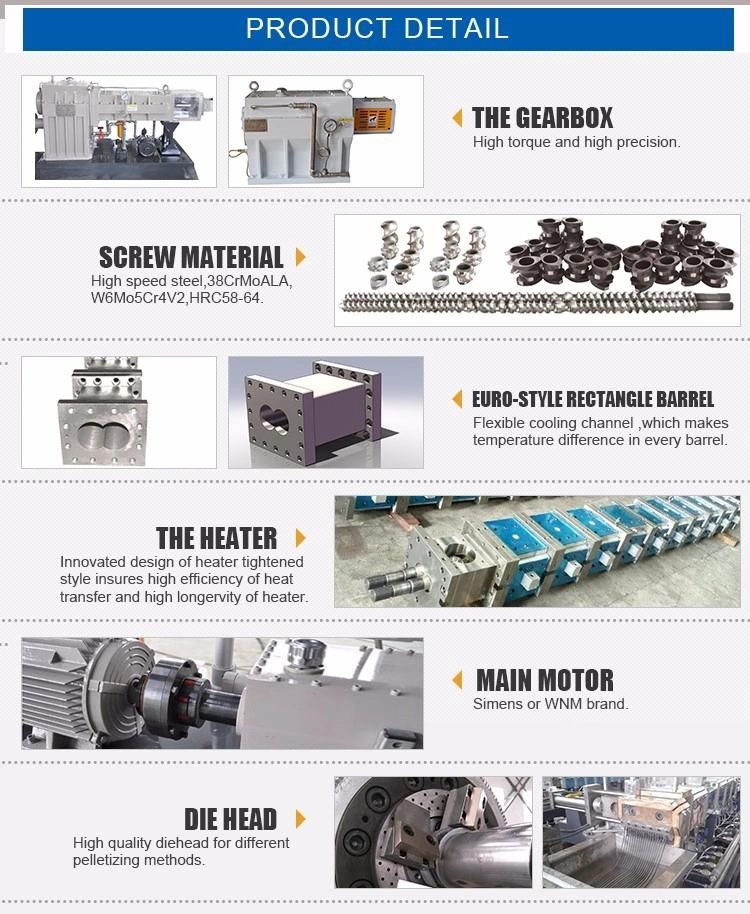

Model NO. TSE SERIES Screw Twin-Screw Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Color as Required Application Granules Voltage 220V/380V Power(W) 55kw Weight 3000kgh After-Sales Service Provided Engineers Available to Service Machinery Overseas Screw Material Stainleeless Steel Diameter of Screw 50.5 mm Screen Changer Hydrulic Screw Changer Transport Package Wood Case Specification CE ISO9001 Trademark Nanjing kairong Origin China (Mainland) Jiangsu, Nanjing City HS Code 84772090 Production Capacity 300 Sets/YearProduct Description

PP/PE Waste Plastic Granules Pellet Machine for Recycling Granulator Price/Waste Plastic Granules Making Machine

Description:The machines are designed by suing the "toy bricks" principle, the screw configuration, barrel setup, L/D or mode

of feeding and venting, screen changing, way of granulating, and the control mode can be optimally adjusted

according to different materials properties and requirements in consideration of the versatility in each general

applications.

Co-rotating parallel twin-screw extruder is widely used in general plastic, engineering plastic and thermal plastic

rubber, etc polymer materials such as filling, reinforcing, toughening, etc blending modification, as well as the

special fiber and special adhesive, etc processing fields

Parameter Table:

| Mode | Diameter (mm) | L/D | Speed (r/min) | Power(kw) | Capacity (kg/h) |

| TSE-40B | 41 | 32-52 | 600 | 45-55 | 100-160 |

| TSE-65B | 62.4 | 32-64 | 600 | 90 | 250-350 |

| TSE-75B | 71 | 32-64 | 600 | 132 | 350-550 |

| TSE-75D | 71 | 32-64 | 600-800 | 200-250 | 600-800 |

| TSE-95B | 93 | 32-64 | 600 | 315 | 800-1200 |

1.Strand Extruders for Filling/Compounding and Reinforcing

Fibre reiforcement : glass fibre, carbon fibre reinforced PP, PA, PBT, ABS, PC, POM, PPS, PET, etc.

Fibre reiforcement : glass fibre, carbon fibre reinforced PP, PA, PBT, ABS, PC, POM, PPS, PET, etc.

Incorporation of Fillers: Caco3, Talc, TiO2, carbon black,filled PE, PP, or EVA, etc.

Cable Compounds: cable sheath, cable insulation compounds of LDPE, HDPE, LLDPE, MDPE; radiation-crosslinkable

compounds, optical fibre protection compounds, heat-shrinkable polymer compounds.

Special Compounds: PPR pipe compounds, PE compounds for crosslinked pipes, tobacco filter compounds, etc.

High Concentration Color Masterbatches: PE, ABS, PS, EVA, PP,etc. with high concentration of pigments and other

processing aids.

Masterbatches with Flame-retardants: PE, ABS, PS, EVA, PET, PP, etc. with flame retardants and other additives.

The twin screw strand extruder also fit for PET bottles/ flakes recycling.

2. Water Ring Extruders for Filiing/Compounding/Modificating

2. Water Ring Extruders for Filiing/Compounding/Modificating

PE, EVA etc. Filled with CACO3,talc,TIO2,carbon black etc.

Cable sheath, cable insulation compoundes of LDPE,HDPE,LLDPE,or MDPE;

Radiation-crosslinkable, heat-shrinkable cable compounds;

PPR pipe compounds, PE compounds for crosslinked pipes;

TPR, TPU thermoplastic elastomers; EVA and hot-melt adhesives;

Color concentrations of PE,ABS, PS,EVA,etc;

Flame retardant master batches of ABS,PS,EVA,etc;

Master batches with PE,PP,PS,etc carriers for degradation applications.

3.Air-cooling Extruders

Enforcing modification:PE,EVA etc.+CaCo3,Talc, TiO2,Carbon black.

Degradable master batch: PE,PS etc.+starch,additive etc.

Anti-flame master batch: PE, EVA etc.+Sb2O3, Mg(OH)2,AI2(OH)3 etc.

4. Underwater Extruders

1.The main material is PE+CaCO3

2.The metering feeders are equipped with single screw, twin screw, hollow screw, forced feeding ,side-feeding, etc

3.Different requirementsof feeding, such as power, pellet, lump and luqid material.

5.Single Screw / Two Stage Single Screw Recycling Extruder Machine

The single screw extruder fit for clean PP/PE film or PP/PE/ABS flakes recycling, not for compounding masterbatch

make.the final end product could be used to make plastic carrying bags or new film.

FAQ

1. Q:Are you factory or trading company?

A: We are manufacturer.

2. Q: What makes you different from other suppliers?

A: 1) firstly,our factory is very professional in twin screw extruder for many years, and our machine's

quality is best in our field and our price is also competitive from other suppliers.

2) second,our service is very excellent.and our engerneers is avaliable to service the machine overseas

and if you have any questions you can contact us at any time,we will reply you in 24hours.

3. Q:What is the payment?

A: 1) T/T payment; 30% T/T in advance ,balance before shippment. 2) L/C or contact us for other ways.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23