Dry Pellet Making Equipment Floating Fish Feed Pellet Maker Equipment

Qingdao Baigu Plastic Products Co., Ltd. / 2022-07-05

- Power Source:Electric

- Process:Thermal Processing

- Automatic Grade:Full-Automatic

- Application:Dog, Fish, Cat, Bird

- Feed Type:Grain

- Customized:Customized

=== Base Info ===

- Model NO.:TSE65,70,85,90

- Product Name:Fish Feed Pellet Machine

- Capacity:100kg,H-2000kg,H

- Drying Machine:Multi-Layer Dryer

- Voltage:It Depends on Clients′ Factory

- Drying Power:Electricity,Natural Gas,Diesel Oil

- Screw:38CrMoAl

- Material of Machine:Stainless Steel

- Processing Line:Mixing, Extruding, Drying, Flavoring, Packing

- Manufacturer:10 Years′ Factory

- OEM:Yes

- Certificate:ISO9001, SGS, Ce

- Extruder Type:Twin-Screw Extruder

- Feed Size:1-15mm

- Motor:Siemens, ABB and China Brands

- After-Sale Service:Available

- Transport Package:According to Clients′ Requirments

- Specification:It depends on machines′ model

- Trademark:Sunward

- Origin:Jinan, China

- HS Code:8438800000

- Production Capacity:20 Sets , Month

=== Description ===

4.Voltage Requirement

Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers'

Local voltage according to different countries

5. All the machines are made by stainless steel, this line is with reasonable design and with high

automation; the screws are made by alloy steel, with building block system structure and self-

cleaning function.

6. Features of floating fish feed pellet machine

(1) High automatic degree , all machines just need 2 worker for operation.

(2) Wide range raw material . Not only cereal flours, but also fresh meat , bone are ok.

(3) Various sizes of fish feed could be processed just by changing the mold.

(4) Intelligent electric heating device is adopted which can improve the feed expansion rate.

(5) High temperature and high pressure cooking process can kill the salmonella and bacterial

infections and also makes the fish feed easily to digest.

(6)The wet type machine needs a boiler to make steam which can conduct steam to the

conditioner and ripen the raw material in advance.

II.Different shapes of die , various size of fish feed

You just need to change different shapes of die in the outlet of extruder machine. Then you could get various sizes of fish feed. The size of fish feed could be 2mm-15mm generally.

The following videos for your reference :

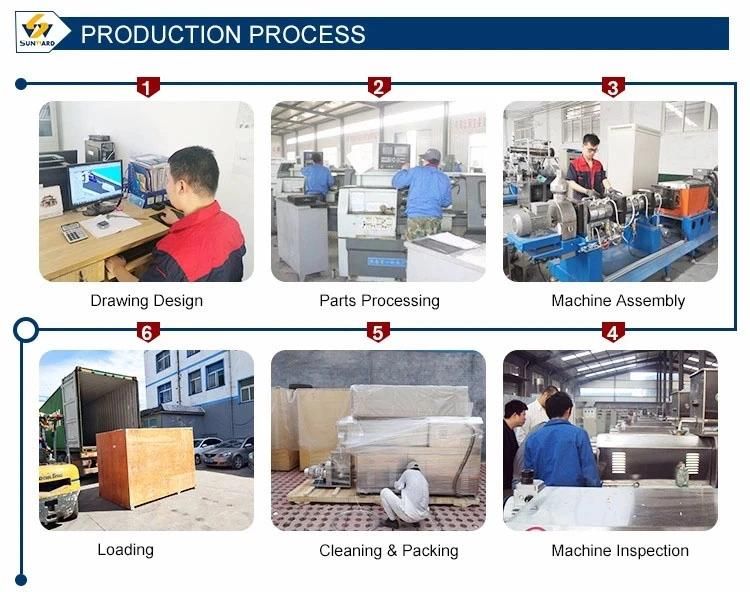

III.Production Process

IV. Packing and Shipping

Two layers of packing before delivery---Plastic film inside, Plywood case outside according to your requirements.

The transport type could be by sea, air as well as train.

V. Our Services

-- Before sale service

1.Provide the free consultation of the equipment.

2.Provide the standard device and the flow chart.

3. According to the clients' special requirement, offering the reasonable plan and free design

helping to select the equipment.

--Services during the sales:

1.Help client design the factory and offering professional advice, free engineering drawing for the

factory layout

2.Welcome to visit our factory or the domestic clients' factory.

3.Inspect the machine before leaving the factory.

--After sale services:

1. Oversea install and debug the equipment.

2. Train the first-line operator.

3. Provide the basic formula.

4. Operation/ Service/ Maintenance Manual: Provided In English.

5. 1-2 engineers will be arranged for customer

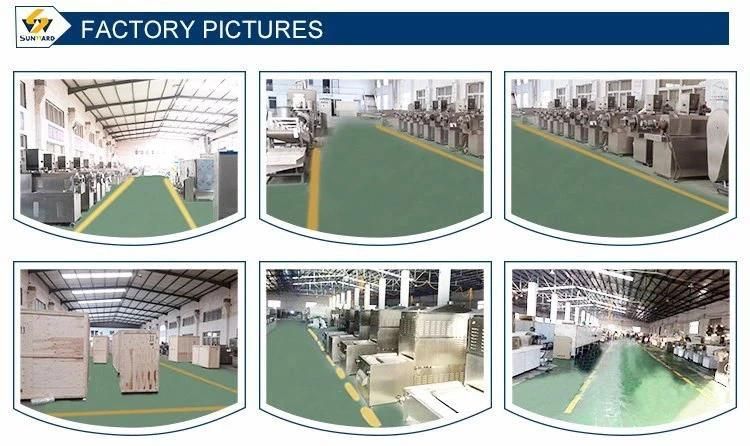

VI.Company Information

VII. FAQ

Q1. Are you a factory or a trading company ?

Sunward : We are a professional manufacturing factory with trading department.

Q2. Could we visit your factory to check the machines ?

Sunward : Of course . Welcome to visit our factory warmly !

Q3. Where is your factory ?

Sunward : Our factory is located in Jinan city, China. It takes you 3 hours by air or 10.5 hours by high-speed train from Guangzhou to Jinan. And if you are from Shanghai, then it only needs 1.5 hours by air or 4 hours by high-speed train. What's more, we could pick you up when you arrived airport or train station.

Q4. Could we test our own raw materials with your machines before making order ?

Sunward : We would like to test your material with our machines freely for you.

Q5. What's your payment terms ?

Sunward : The general one is 30% as deposit, and then the balanced money is paid before delivery. But we could also accept L/C.

Q6. What about your after-sale service ?

Sunward: If you order the full-automatic production line machines, we could dispatch our engineer to your factory for installation and training. And if it is single machine, then we could send you the operation video.

VIII. Contact Information

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23