Synthetic Resin Roof Tile Extrusion Machine Plastic Roof Tiles Making Machine

Fujian Quanzhou Huazuan Diamond Tools Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. ACEMINE880 Customized Customized Condition New Transport Package Plastic Film Package and Loaded Into The Container Specification 28m*5m*5m Trademark Acemien Origin Jiangsu Province HS Code 84772090 Production Capacity 1000 Sets/YearProduct Description

Synthetic Resin Roof Tile extrusion machine Plastic Roof Tiles Making machineThe Synthetic Resin Roof Tile extrusion machine Plastic Roof Tiles Making machine is designed professional to produce the roofing sheet with trapezoidal U panel profile or the corrugated wave profile roma roof tile PVC roma roof tile plastic extruder machine line. This Synthetic Resin Roof Tile extrusion machine Plastic Roof Tiles Making machine can produce both doule layer sheet or single layers sheets. If you need the double layers sheet, then you can add one SJ 65 extruder. So theSynthetic Resin Roof Tile extrusion machine Plastic Roof Tiles Making machine is just with one SJ80/156 extruder.

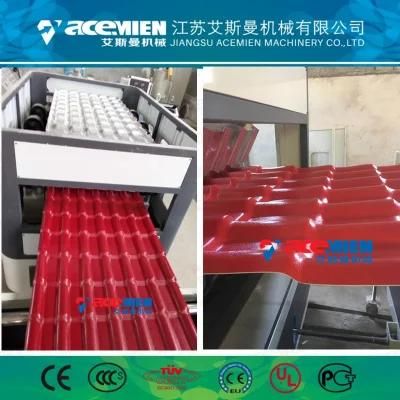

Below are some pictures of the Synthetic Resin Roof Tile extrusion machine Plastic Roof Tiles Making machine for your reference:

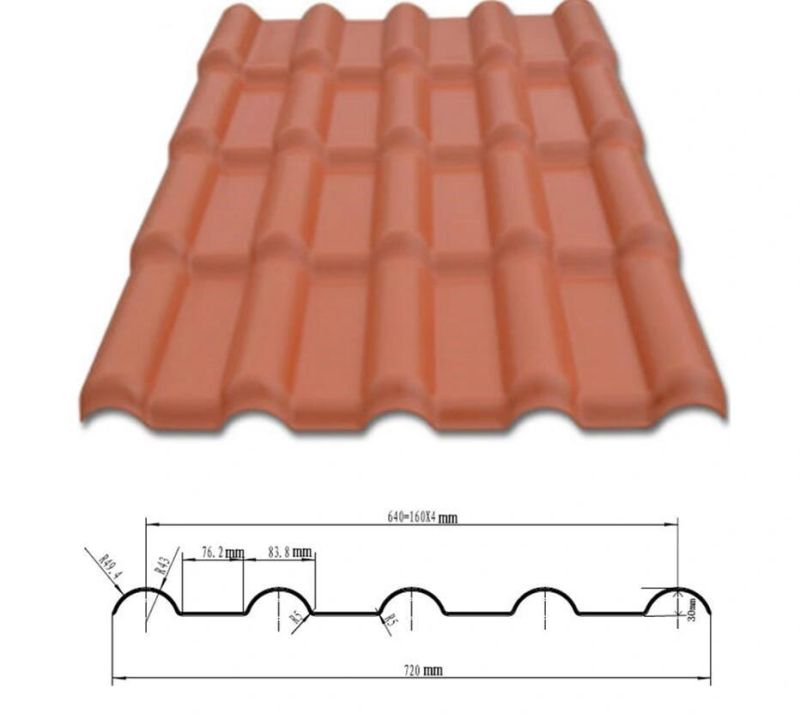

Synthetic Resin Roof Tile extrusion machine Plastic Roof Tiles Making machine profile specification is as below, for your reference, If you need different sizes of the profile, such as the pitch height, the pitch width, and pitch distance, you can let us know, so that we can make the drawing for you, also you can delivery your sample to us, then our engineer can make the drawing according to your samples.

For theSynthetic Resin Roof Tile extrusion machine Plastic Roof Tiles Making machine, its working process as below:

Screw loader for the SJ 80, and main SJ80 extruder, which is 55KW, 3 Phrase, Siemens motor. Double screw extruder. SJZ 80/156 conical twin-screw extruder(PVC).

TheSynthetic Resin Roof Tile extrusion machine Plastic Roof Tiles Making machine Extrusion mould Calibration mould and trimming device.

The specifications is as below:

Flat extrusion mould:

Mould type: clothes rack

Material of die-head: 5CrNiMo steel

Effective width of mould lip: 1100mm,1300mm

Adjusting arrange of mould thickness: 1-4mm

Heating power of each zone: 5KW×7sets

Heater: stainless steel stick Polishing precision of mould lip flow plane: 0.015-0.02(um), others: 0.02-0.03(um)Electroplate: mould flow plane treatment by hard chrome plating, thickness 0.03-0.04mm, hardness: 60-65RocKWellc, surface treatment by chrome plating at thickness: 0.01-0.02mm

Method of material input: central square opening input

Method of Installation: flat extrusion install

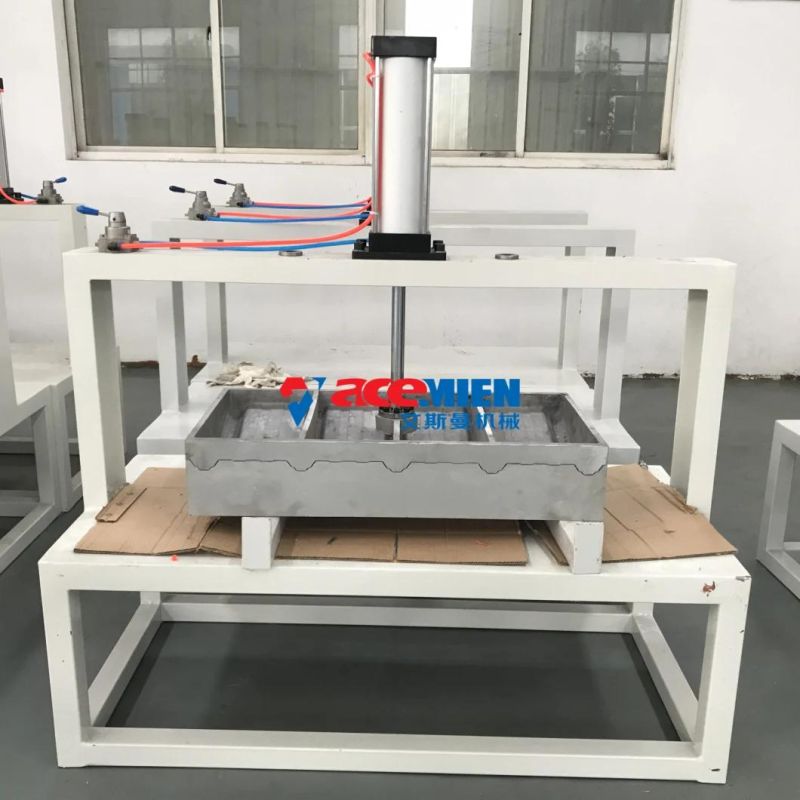

The Synthetic Resin Roof Tile extrusion machine Plastic Roof Tiles Making machine is as below:

Quality of blade: 2pcs

Material of blade: quality alloy steel

Width can be adjustable

Material:45#steel,treatment by hard chrome plating, polishing and quenching

Hardness of chrome plating: 0.04mm, degree of finish:0.8,

Length:1000mm

Width:1250mm

Rise and drop method of mould: pneumatic

Quantity of cylinder:4sets

Fine adjustment method: manual

Cooling water:5-6 ton/hour

Quality of blade: 2pcs

Material of blade: quality alloy steel

Width can be adjustable

Material:45#steel,treatment by hard chrome plating, polishing and quenching

Hardness of chrome plating: 0.04mm, degree of finish:0.8,

Length:1000mm

Width:1250mm

Rise and drop method of mould: pneumatic

Quantity of cylinder:4sets

Fine adjustment method: manual

Cooling water:5-6 ton/hour

The haul off Unit:

Driving method: Adopt ABB frequency inverter control,

Speed:0.3-3m/min

Haul off roller material: Neoprene CR

Rise and drop method of mould: pneumatic

Fine adjustment method: manual

There are auxiliary equipments for the also Synthetic Resin Roof Tile extrusion machine Plastic Roof Tiles Making machine, The oven for ridge cap forming, the press machine for ridge cap forming and related molds, the Pulverizer to recyce the roofing sheets.

Some customers are wondering the raw material of the Synthetic Resin Roof Tile extrusion machine Plastic Roof Tiles Making machine, we can offer the raw material details for your reference: PVC powder, CaCO3, CPE, PE-WAX, Stearic acid , Compound stabilizer ,ACR, paraffin.

About the price of the raw material, we can offer you a list, if you need.

And more, we have experienced engineers who are working on machine insatalltion and raw material mixing, so that can help you to produce the perfect roofing sheet once the Single-layer Corrugated PVC Roof Tile Production Line reach your factory.

My name is Laura, who is working on the service to help you order the Single-layer Corrugated PVC Roof Tile Production Line, if you have any questions about the Glass Fiber Reinforced Resin Roof sheet extrusion line, and the raw material, and any other questions, please feel free contact me, please!

My name is Karry, please feel free contact me, please!

Whatsapp: +86 18913298068

Phone/ Wechat : +86 18205059535

please contact me please if you want to know more about this machine line.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23