100W Laser Clearing Machine for Rust Removing Paint Cleaning

Taizhou Huangyan Lipeng Machinery Mould Factory / 2022-06-23

- After-sales Service:Free Spare Parts

- Power:200w

- Control Type:Handheld

- Warranty:2 Years

- Laser Power:50W,100W

- Scan Head Brand:Sino-Galvo

=== Base Info ===

- Model NO.:LC-M1

- Cooling Way:Air Cooling

- Laser Wavelength:1064nm

- Laser Frequency:20-200kHz

- Transport Package:Plywood Box

- Specification:630mmX590mmX290mm

- Trademark:Lansen

- Origin:Jinan China

- HS Code:8456110090

- Production Capacity:300 Sets,Month

=== Description === The high-energy density laser beam is used to irradiate the surface of the workpiece, so that the dirt, rust or

The high-energy density laser beam is used to irradiate the surface of the workpiece, so that the dirt, rust or

coating on the surface evaporates or peels instantly, so as to achieve cleaning and purification.

How does laser cleaning work differently to the other more traditional methods:

There are some key problems that lasers have helped to address and solve.

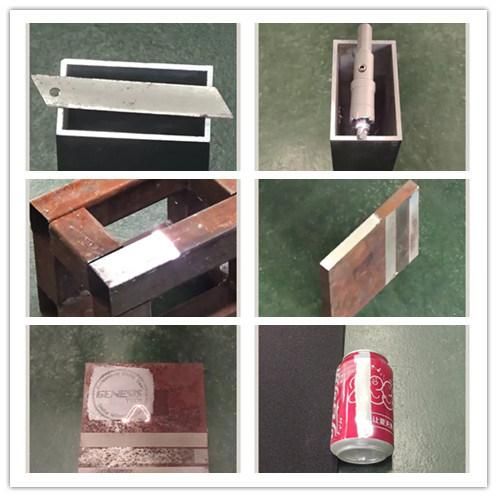

Fiber laser rust removal cleaner can do fast cleaning of rust, painting, oil from metal surface, like tinplate heavy rust remove, wire brushed thick rust remove, rusted tool mold cleaning, painting cleaning, etc.

It have following features:

1) Non-contact cleaning, without damage to parts matrix.

2) Precise cleaning, with accurate location, precise size and selective cleaning.

3) No chemical cleaning fluid, no consumables, safe and environmental protection.

4) Simple operation, the power can be charged, and the automatic cleaning

can be realized by hand or with the manipulator.

5) Cleaning efficiency is very high and saving time.

6) The laser cleaning system is stable and little maintenance requirement.

Laser cleaning, on the other hand, is non-contact and non-abrasive, and so will only irradiate the material that you want to get rid of. This makes the process in particular, ideal for cleaning intricate and textured materials. You also have a great deal of control over the beam, meaning you can achieve the desired depth that you want to. Further to this, you can irradiate the whole surface layer of a material, or a much thinner layer, say the topcoat of paint, but not the primer below. Or, should you wish, you can just clean a very small section. If using another process which simply blasts the material, it is hard to enjoy such a high level of control. One of the key benefits in the way that laser cleaning works is that not much waste is left over due to the irradiation process; the substrate is simply vaporised rather than left as waste. The majority of the waste that is left over comes as dust particles and can be easily collected and removed by the user.

It is mostly dust particles that are left behind from the laser cleaning process As if all the above isn't

enough, the laser cleaning process is also much faster, leaving staff more able to complete other work and not spend all of their time cleaning!

Parameters:

Product Details:

1.Switch

Humanized control system, easy to learn, dust proof design.

2.Galvanometer Scanner

It is equipped with automatic scanning system, friendly operation process.

3.Back Side of Machine

Packaging&Delivery:

About Us:

About Us:

Company Profile:

FAQ:

FAQ:Q: How can I choose suitable machine?

A: Please communicate with us via inquiry or email, we can guide you. Please kindly tell us:

1) .What work table size you will need?

2).What work you will do?

Q: What's your payment terms? Delivery time and MOQ?

A: We accpet T/T(bank transfer), L/C, Paypal, Western union etc. Usually we need 30% as deposit, balance paid before shipment.

Delivery Time: 3-5 days after payment

MOQ: 1set

Q: If I bought a machine, how could you make it safe while shipping.

A: We have a professtional package suitable for oversea transpotation. Machine will be fixed well in the case.

Q: What's your quality control system?

A: All machines will be tested after finished. We have QC department response for this job. And we already got CE approved.

Q: If I don't know how to use the machine, can you teach me?

A: 1) There is a DVD disc including machine user manual and software user manual c/w machine.

2) Online (skype & phone)

3) Remote desktop software (Teamviewer)

4) Demo Video

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23