Wet Diamond Polishing Pad for Granite and Marble Wet Polishing

Xuzhou Selead Packaging Material Co., Ltd. / 2022-06-27

- Manufacturing Process:Abrasive

- Shape:Dish-Shaped

- Bonding Agent:Resin

- Pad Material:Resin and Diamond Grain

- Type:Standard Flexible Abrasive,Polishing Pads

- Size: ):3"~7"X2.5mm(Thickness

=== Base Info ===

- Model NO.:XGP007

- Application:Forstone and Concretea Polishing

- Grit:50#~5000# ,Buff

- Lead Time:3-7 Days

- Transport Package:Carton

- Specification:Diameter: 3"~7"

- Trademark:Singoon

- Origin:Jiangxi Province, China

- HS Code:680421000

- Production Capacity:50000piece Per Week

=== Description ===

Diameter

80,100,120,150,175mm

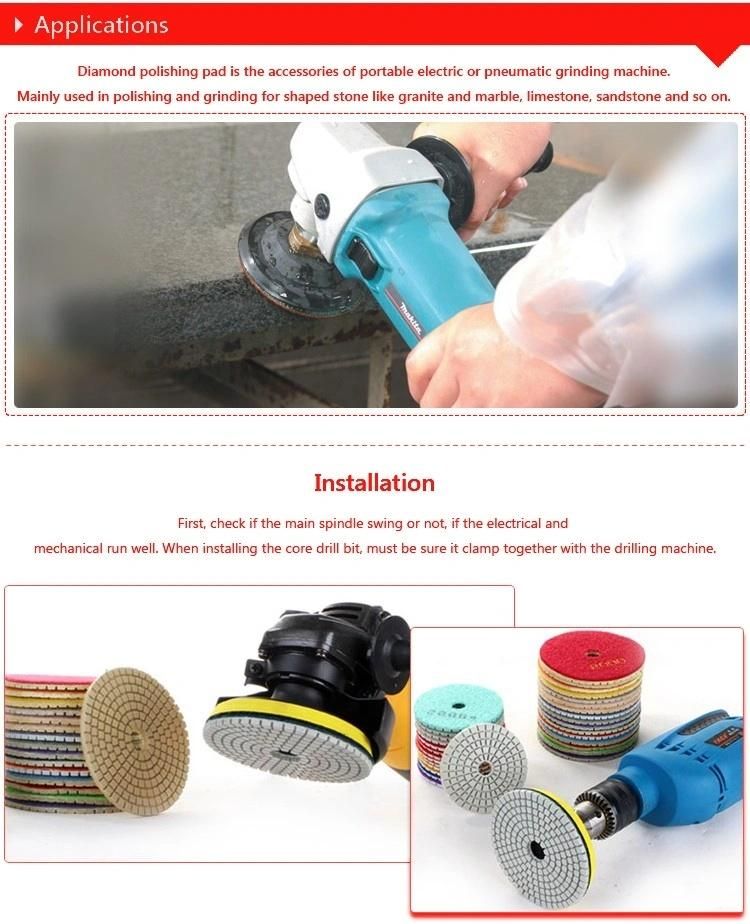

Application of diamond polishing pad

1.Apply to Granite,marble and other kinds of stones

2.High efficiency and remarkable performance polishing with water

3.Run on hand helded grinder and floor machine

Performance

1.High polishing speed without any scratches

2.Glossy polishing surface

3.Longer lifespan

4.Easy for oprating

5.Durable resin compound

6.Velcro backed for quick attachment

7.Very flexible and soft

Wet Polishing Pad Grit

50#,100#,200#,400#,800#,1500#,3000#

Attention

1.Different stone choice close color polishing pad

2.Different Grit apart in different color

3.Use Hand Polishing Machine.The speed of machine must less 4500 RPM,The pressure must less 3kgs/cm2

Diameter:3inch(80mm),4inch(100mm) 5inch(125mm) 6inch(150mm)

Thickness:2.7mm

Grit:50 100 200 400 800 1500 3000

Use type: wet

Application:hand polisher,portable grinder

· Marble· Granite· Natural Stone· Synthetic Stone· Concrete

Working procedure:

Step 1: 50 # for Aggressive coarse grinding

Step 2: 100 # for Coarse grinding.

Step 3: 200 # for Semi Coarse grinding

Step 4: 400 # for Soft grinding / medium polishing

Step 5: 800 # for Extra polishing

Step 6: 1500 # , 3000 # for Final polishing

FAQ:

1 . We want to buy diamond cutting tools from your company, how can we ensure the quality?

First of all, we thank you for your trust on our products. Singoon is a professional manufacturer in stone cutting tools for over 15 years. We are very strict on quality, from the raw material to the end products, we have professional full-time QC to check every process. We consider quality and service as our first life. We would like to share the performance of our segments from our other clients.

If it is possible, we strongly recommend a small trial order, then you will see the performance of our diamond tools directly.

2 . Do you provide FREE Samples if I want to buy from your factory?

Singoon will NOT offering free samples, because diamond tools are high value products, very limited diamond tools companies would like to provide free samples, if you want to check our quality, a trail order is much better.

What's more, people will cherish the samples more by paying it. They will check and make the inspection on the products carefully. On the other hand, the cost for samples is much higher than ordinary production.

3. How is the difference between Laser welding and the high frequency welding blade for granite cutting?

Laser welding blade is more apply to concrete cutting, and high frequency welding blade is suit best for granite cutting.

4 . What is the MIQ and the shipping detail?

You can buy any quantity from us, we suggest you buy it by sets so you can make the test on our products and see its performance.

For delivery details:

Calculate the total weight of your order.

Choose a shipping method.

Check the current freight Rate and calculate shipping charges.

Check the other charges and add together.

For any orders, the weight should over 45kgs(requested by Air Line Companies, otherwise the Airfreight below 45kgs is very high). Kindly noted.

5 . How can I get the best suitable diamond segments?

Offer Singoon more details about your stone and cutting machine:

1. Diamond Disc/Blade for sawing, slicing, splitting or any other applications

2. Stone Hardness, Abrasiveness and Grit Size, pictures or samples if possible

3. Machine used for Diamond Blades/Discs, Bridge Saw, Table Saw, Brick Saw, etc

4. Machine Main Motor, Spindle RPM, Feeding Speed and Cutting Depth

5. Thickness and diameter of Steel Core (blade without diamond segment) for suitable segment size.

6. General request for Blade Life /Cutting Square Meters per blade;

6 . What if your products do not run well?

First, kindly contact us at any time when your found the question. Give us more details as much as possible(such as video, pics). Our technician will analyse the question and help to find out the reason and the solution.

If we can confirm it is our quality problem, we will take our responsibility and make the replacements for you without any hesitation.

For more details and information about the diamond stone cutting tools, feel free to contact us at 7*24, Thank you for your time!

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23