Tuna, Sardine Fish Chicken Meat Corned Beef Luncheon Meat Tin Can Processing Machine ...

DONGGUAN VISTECH IMPORT & EXPORT CO., LTD. / 2022-07-04

- Power Source:Electric

- Warranty:1 Year

=== Base Info ===

- Material:Stainless Steel

- Feature:Easy to Clean

- Certificate:CE SGS Ios

- Application:a Variety of Canned Fruits and Vegetables

- Power Supply:3pH 380V 50,60Hz

- Usage:Plastic, Tin, Glass

- Dimension(L*W*H):Customized

- Packaging:Tin, Glass

- Model No.:Lw

- Product Name:Canned Food Production Line

- Customized:Customized

- Voltage:380V

- Type:Whole Line

- Automatic Grade:It Can Be Customized According to The Output

- Process:Thermal Processing

- Model NO.:LW

- Advantage:The Operation Is Simple

- Transport Package:Wooden Case

- Specification:customized

- Trademark:lw

- Origin:Shanghai

- HS Code:190709000

- Production Capacity:10 Set,Year

=== Description ===

Basic Info.

Model NO. LW Process Thermal Processing Automatic Grade It Can Be Customized According to The Output Type Whole Line Voltage 380V Customized Customized Product Name Canned Food Production Line Model No. Lw Packaging Tin, Glass Dimension(L*W*H) Customized Usage Plastic, Tin, Glass Power Supply 3pH 380V 50/60Hz Application a Variety of Canned Fruits and Vegetables Certificate CE SGS Ios Feature Easy to Clean Material Stainless Steel Advantage The Operation Is Simple Transport Package Wooden Case Specification customized Trademark lw Origin Shanghai HS Code 190709000 Production Capacity 10 Set/YearProduct Description

Tuna,Sardine Fish Chicken Meat Corned Beef Luncheon Meat Tin Can Processing Machine Canned Food Tomato Paste Production Line Machinery Canned Filling MachineProduct Description

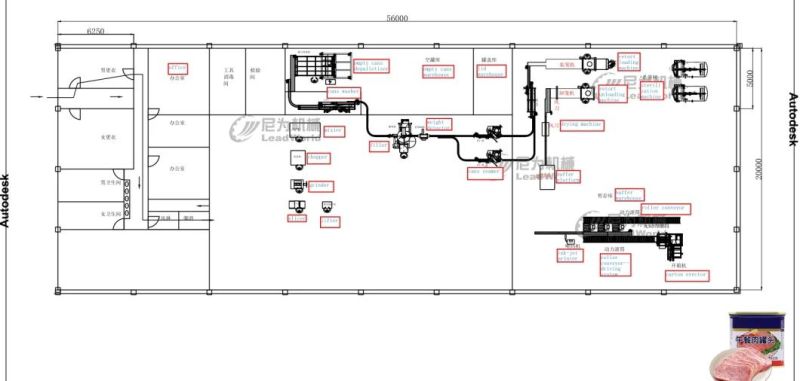

Shanghai Leadworld to provide professional canned tuna fish, canned sardines, canned braised meat, canned beef, lunch meat, canned chicken, canned pig head, canned mutton and other meat products canned production line equipment.

According to the plant area,wen can provide a complete set of production line equipment from raw material processing,washing,filling,sealing,

loading and unloading cages,sterilization until packing,and can provide the entire plant planning and design.

Process flow :

Empty can cleaning → Disinfection → Raw material pretreatment → Filling → Pre-sealing → Exhaust → Sealing (vacuum sealing) → Sterilization → Cooling → Insulation inspection → Finished product

| Mangnetic depalletizer |

| can washing 150 cans/m of 180g |

| artificial filling line Workbench |

| working table |

| batching tank 600L |

| storang tank 1000L |

| punp |

| Circulating soup machine |

| small can sealing machine Different diameter different machine |

| filled can washing |

| automatic cart palletizer |

| Sterilization machine |

| automatic cart depalletizer |

| air dryer |

| flip Turn machiine |

| can labeling machine |

| Ink jet print |

| unbox machine |

| Turning roller |

| Automatic cartoning machine |

| carton sealing |

| power roller line |

| no power drum |

| Conveyor |

| Turn part |

| Motor+transducer |

some installing pictures:

washing line

loading and unloading for sterilization system

Filling Line

Filling Line

our control system

some descriptions of our machineCooling machineExcept Motor and bearings ,other standard parts are made of stainless steel SUS304 / 2B material, in full compliance with the export of food hygiene requirements.

This machine series are suitable for all kinds of vegetables,fruits, fungi's pre-cooking and cooling of the product.Precook temperature and speed can be set according to the technical requirement.

The machine uses SUS304 stainless steel chain plate, mesh belt,mesh belt with high intensity, small scale, difficult deformation, easy maintenance, etc., the

whole machine balanced running, low noise, greatly improving the work efficiency

This machine is heating mode of electric heating.The machine transmission system adopts gear motor speed regulation which

make the conveyor belt speed adjustable.

Selecting conveyorApply to primary raw materials selecting and cutting treatment.

The machine adopts disassembly design.Quantity of working station can be customized according to clients'actual demand.

The whole machine adopt SUS304 stainless steel. 1.1 Lifting conveyor main body side chain plate:Plate thickness:δ2.0mm Material:SUS304.

When produced according to the actual size.

1.2 Roller:Material SUS304,diameter is based one the actual

load,cooperate with the plus or minus tolerance.

1.3 Riding wheel:Material Nylon processing molding,diameter is based one the actual load,cooperate with the plus or minus tolerance.

1.4 Bun foot:Nylon injection molding,Cooperate with stainless steel adjusting screw M16.

1.5 Guardrail part adopts big Caluminum trackCooperate with wear-resisting sheath;

1.6 Connecting plate:plate wicknessδ3.0mm Material:Stainless steel bending forming;

1.7 Connection between mesh belt:Nylon board or ball, according to the customer's product selection.

1.8 Accessories:Mounted Bearings,kinds of SUS304 screws,etc.

Conveying carrier part

2.1 Module length:According to the effective length*widthness (mm)(When produced according to the actual size);

2.2 Module belt varieties:Flat grid, grid, according to the actual situation to choose material.

2.3 Material:POM,PP,PE

2.4 Color:White,Blue,Green.

3.Power system

3.1 Gear motor:Worm gear and worm gear motor,

Protection class IP55,Power P=1.5KW/0.75KW;

3.2 Speed:V=0-25 Meter/MIN;

3.3 Speed choice: Denmark D,anfoss inverter frequency control motor speed.

4.1 Electric cabinet material:1.5mm SUS304 Stainless steel plate bending welding forming.

4.2 Electronic components:disconnector,AC contactor, button switch,etc. Brand: S,chneider,France.

can washing

Descriptions:

It is applied to clean and dry outside surface of all kinds of canned fruit,canned meat,bottled sauce and all kinds of drinks.(specializedin washing and drying the adhensive sugar water and other adhenion outside of the sealed canned products or beverage), applying for tin cans,glass bottles and plastic bottles.

Machine features:

The whole machine adopts SUS304 stainless steel manufacturing, reduce pollution, ensuring healthyof the products.

High degree of automation, automatic tempreture control, good finish washing.

Using Acrylic hood, the whole cleaning process can be seen.

Double cleaning design, washing water can be recycled.

Advanced machine design structure,easy to clean,water tank large diameter drain hole.

Parameters:

Capacity: 50-100cans/min,stepless speed.

Pipeline speed:6-30m/min

Scope of application:Cans Dia 40-180mm,height:40-200mm

Size:4600*800*1400mm

Motor:0.75kw, 10-50 r/min

Sanitary pump:0.75kw*6 12.5T/h

Fan:7.5kw*2

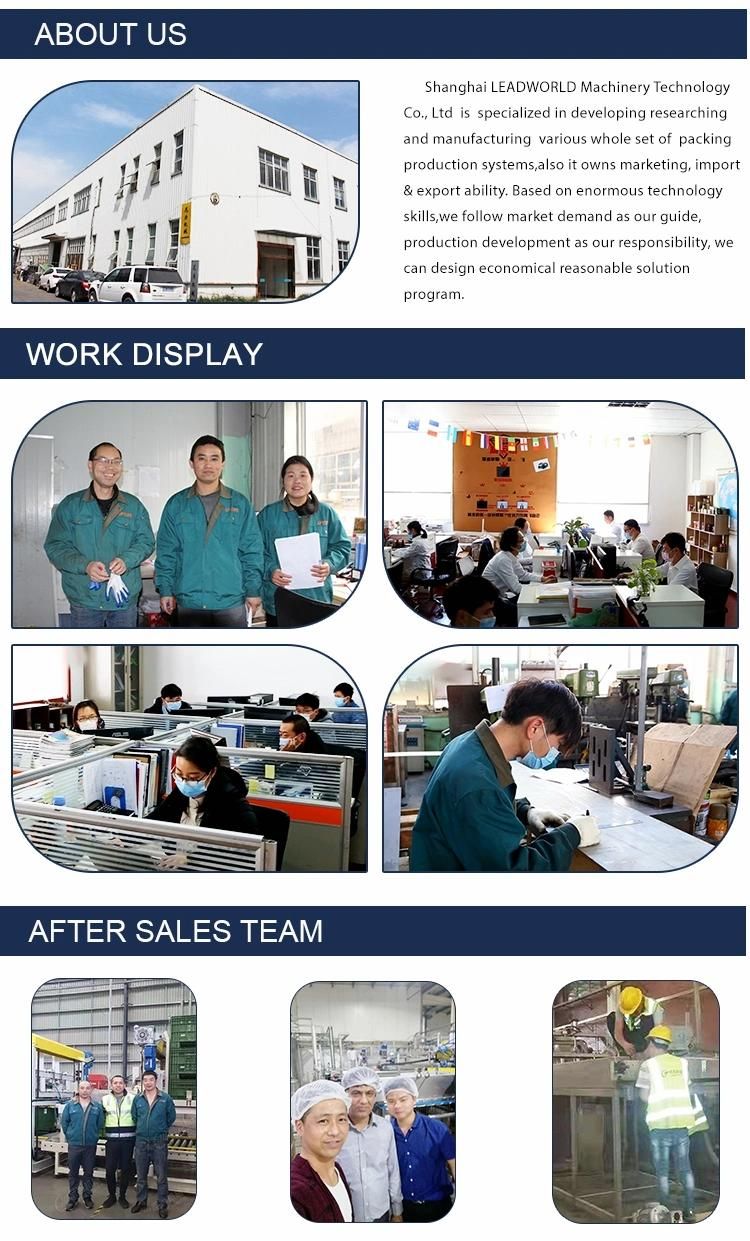

About Us

Cooperative Customers

Cooperative Customers

FAQ

Q1:Are you manufacturer or trading company?

We are manufacture verified by ALIBABA and we have our own design team.

Q2:Where are you located? Is it convenient to visit you?

We are located in Shanghai. Traffic is very convenient.

Q3:How can you guarantee quality?

1.We have completed working system and procedures and we follow them very strictly.

2.Our different worker is responsible for different working process, their work is confirmed,and will always operate this process, so very experienced.

3.The electrical pneumatic components are from the world famous companies,

such as Germany's Siemens, Japanese Panasonic etc.

4.We will do strict test running after the machine is finished.

5.Our machines are certified by CE,SGS,ISO.

Q4:Can you design the machine according to our requirements?

Yes. We not only can customize the machine according to your technical drawing, but also can design new machine according to your requirements.

Q5:Can you offer overseas technical support?

Yes. We can send engineer to your company to set the machine and train your worker if needed.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23