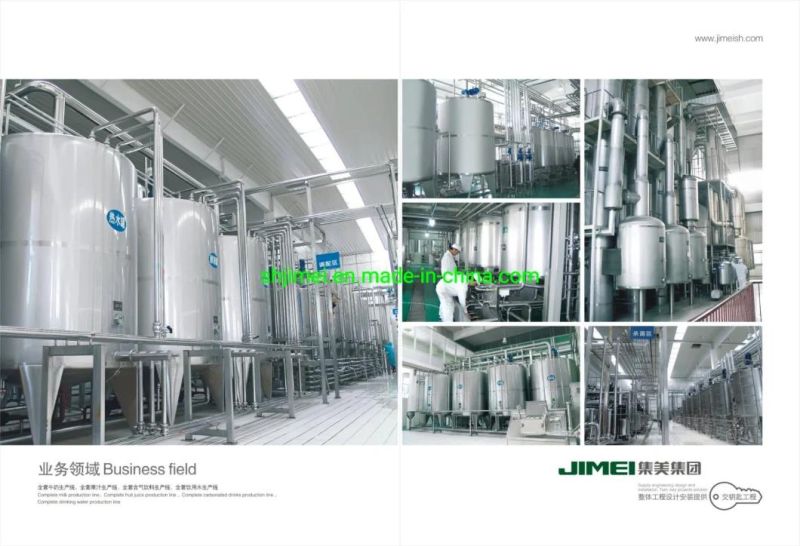

Powder Milk Production Line Milk Powder Making Machine

Shanghai Yongguan Adhesive Products Corp., Ltd. / 2022-07-04

- Certification:CE, ISO9001

- Power Source:Electric

- Warranty:12months

- After-sales Service:Engineers Available Over Sea

- Automatic Grade:Automatic

- Application:Milk, Yogurt, Milk Powder, Cheese

=== Base Info ===

- Transport Package:Packed in Nylon Cloth and Plastic Film

- Energy Consumption:Low

- Run:Stable and Reliable

- Control:PLC, Touch Screen

- Work:Full Automatic

- Capacity:200L to 20000L Per Hour

- Processing:Complete Production Line

- Producing:All Kinds of Milk Products

- Manufactured:Shanghai Jimei Food Machinery Co., Ltd

- Project:Complete Milk Yogurt Processing Line Machine

- Customized:Customized

- Specification:CE ISO

- Trademark:Shanghai Jimei

- Origin:Shanghai, China

- Production Capacity:2 Units Per Week

=== Description ===

Basic Info.

Customized Customized Project Complete Milk Yogurt Processing Line Machine Manufactured Shanghai Jimei Food Machinery Co., Ltd Producing All Kinds of Milk Products Processing Complete Production Line Capacity 200L to 20000L Per Hour Work Full Automatic Control PLC, Touch Screen Run Stable and Reliable Energy Consumption Low Transport Package Packed in Nylon Cloth and Plastic Film Specification CE ISO Trademark Shanghai Jimei Origin Shanghai, China Production Capacity 2 Units Per WeekProduct Description

keywords:

Turnkey project Complete milk powder Production Line,

Milk Powder Processing Line,

Milk powder making machinery:

goat milk processing line

goat milk drying production line

milk powder production line

milk powder drying and filling line

We are looking for sole agent for each country, please contact us if you are interested.

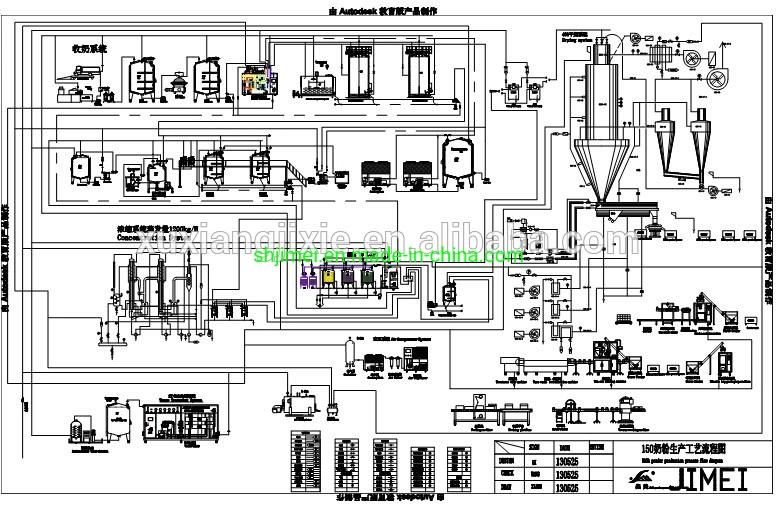

Working principle and configuration options

The solution, emulsion, suspension liquid or slurry are sprayed into fine beads in the hot air, going down from the top of the drying chamber to the bottom, the water will be evaporated to and the product becomes powder or granular product.

Induce hot air from the top of drying tower, at the same time, pump the material liquid to the top of the tower by screw pump or peristaltic pump, the feeding solution becomes into fine beads or small droplets through the atomizer. When the droplets meet the high temperature hot air, the water will be evaporated immediately, and the material liquid is dried into dry product in a very short time, the product is discharged from the bottom of the drying tower, or from the cyclone (depend on the configuration). When the hot air contacts with the droplets, the temperature declines significantly, and the humidity increases greatly, and then will be exhausted by exhaust fan. The fine powder in the air will be collected through different separating devices

There're different fine powder separation and recovery devices, such as cyclone (the common type and various combination type), bag filter, cyclone + bag filter, cyclone + wet scrubber, and bag filter + wet scrubber etc. We should different fine powder separation and recovery devices as per the characteristics of product and requirements of customer.

Depend on the product features and requirements, we might install secondary drying and cooling system (such as ZLG vibration fluid bed or pneumatic transportation), formulation system or powder sieving system etc after the spray dryer, or dehumidifier.

Notes for Inquiry:

1. Liquid material name and physical properties: Solid contents (or moisture contents), viscosity, surface tension, pH value, etc. If there's any other liquid, such as organic solvent, please specify the name and percentage clearly.

2. Product characteristics: Final moisture content required, the range of particle size, and heat sensitive temperature etc.

3. Special requirements (if any): Range of specific bulk density, color, and flavor etc.

4. Working capacity (kg/h or ton/h). If the capacity is based on per day, per month or per, please also indicate the working hours.

5. Heat source: It could be the pressure of steam, electricity, coal, oil, natural gas, LPG and other combustible materials.

6. Control requirements: The way to control the air inlet temperature, liquid supply system, pneumatic hammer etc, and the type of the system control (normal push button type, PLC+HMI, and PC system etc)

7. Fines collection type: Depending on the product characters and environment protection requirements, we have following options, cyclone, bag filter, wet scrubber and their combinations.

8. Other special requirements: Dimensions of the workshop, height limit and special electricity requirements etc.

Our company can design customized milk production lines in accordance to the customers' requirements. The production capacity varies from 1000L/h to 10000L/h according to customer's need

Note: Jimei milk production lines can be widely used to produce milk powder, UHT milk, pasteurized milk, setted milk, stirred milk, milk drink, yogurt, ice cream, condensed milk, and so on.

OUR TEAM

OUR CERTIFICATES AND PATENTS

OUR EXHIBITION

OUR PARTY

WHO TRUST US

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23